Acroturn Industries Inc.

Late Model & Multi-Axis Aerospace Machining Facility

Date

Tuesday, June 23, 2020

Start Time

10:30 AM EDT

Inspection

BY APPOINTMENT ONLY. Please email [email protected] to arrange a date and time.

Removal

All assets must be removed no later than Friday, July 17 by appointment only.

Industry

FEATURING: KITAMURA (2011) MyCENTER HX400iF, high speed CNC twin pallet horizontal machining center w/ 13,000 RPM, FANUC 16i-MB CNC control, ATC, etc.; (2) HYUNDAI KIA (EST 2009) SKT250TTSY, CNC multi-axis, opposed spindle and twin turret live milling centers equipped with MISTBUSTERS, tool probes, FANUC 18i-TB CNC controls, etc. (REPLACE OVER 300K NEW EACH - MANY LIVE MILLING HOLDERS AVAILABLE FOR EACH MACHINE); HYUNDAI WIA (2014) KIT-250, high precision CNC gang style turning center; FORTUNE V-TURN 26, CNC turning center w/ MISTBUSTER, FANUC CNC control, etc.; HYUNDAI (2003) SPT V500 D, 4 axis CNC twin pallet vertical machining center; HYUNDAI (2001) SPT-V550D, 4 axis CNC twin pallet vertical machining center; HYUNDAI 4 axis CNC dial type vertical machining center; LARGE ASSORTMENT OF high precision carbide and conventional tooling, machine tool accessories, CNC rotary axis units, inspection equipment, general machining support assets, facility support assets & MORE!

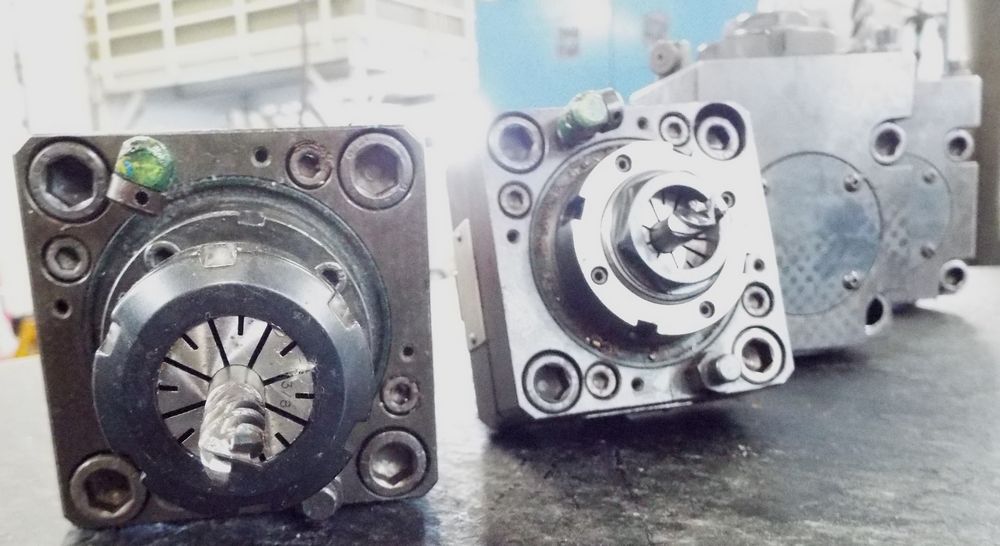

CNC TURNING & LIVE MILLING CENTERS

- HYUNDAI KIA (2009) SKT250TTSY CNC multi-axis, opposed spindle twin turret live milling and turning centers equipped with FANUC 18i-TB CNC controls, (2) 10” hydraulic chucks, 30.70” swing over bed, 15.35” maximum turning diameter, 35.43” maximum machining length, 2.99” bar capacity, travels X1-10.63”, X2-7.48”, Y-4.72” (+/- 2.36”), C1/C2-360,000 positions in 0.001 degree increments, (2) 12-station turrets with live milling, 4,000 main spindle RPM, 4,000 sub spindle RPM, 20 HP spindle motor, coolant, chip conveyor, tool checker arm, MISTBUSTER mist collector, (200-220V/3PH/50-60HZ) s/n: G3737-0006

- HYUNDAI KIA (2009) SKT250TTSY CNC multi-axis, opposed spindle twin turret live milling and turning centers equipped with FANUC 18i-TB CNC controls, (2) 10” hydraulic chucks, 30.70” swing over bed, 15.35” maximum turning diameter, 35.43” maximum machining length, 2.99” bar capacity, travels X1-10.63”, X2-7.48”, Y-4.72” (+/- 2.36”), C1/C2-360,000 positions in 0.001 degree increments, (2) 12-station turrets with live milling, 4,000 main spindle RPM, 4,000 sub spindle RPM, 20 HP spindle motor, coolant, chip conveyor, tool checker arm, MISTBUSTER mist collector, (200-220V/3PH/50-60HZ), s/n: G3737-0021

CNC TWIN PALLET HORIZONTAL MACHINING CENTER

- KITAMURA (2011) MyCENTER HX400iF high speed CNC twin pallet horizontal machining center with FANUC 16i-MB CNC control, (2) 15.7”x15.7” pallets, travels X-28.9”, Y-24.0”, Z-24.0”, W-360,000 positions in 0.001 degree increments, 26” maximum distance spindle center to table top, speeds to 13,000 RPM, CAT40 spindle taper, 50-station ATC, 20 HP spindle motor, shower & high pressure coolant through spindle, chip conveyor, (200-220V/3PH/50-60HZ), s/n: 82025

CNC TWIN PALLET VERTICAL MACHINING CENTERS

- HYUNDAI (2001) SPT-V550D 4 axis CNC twin pallet vertical machining center with SIEMENS CNC control, (2) 25.59”x16.14” pallets, travels X-22.44”, Y-16.14”, Z-22.83”, W-360,000 positions in 0.001 degree increments, 30.59” maximum distance spindle nose to table top, speeds to 10,000 RPM, CAT40 spindle taper, 24-station ATC, 16 HP spindle motor, coolant, chip tray, 220V/3PH/50-60HZ, s/n: 4491B028

- HYUNDAI (2003.12) SPT V500D 4 axis high speed CNC twin pallet vertical machining center with SIEMENS SINUMERIK CNC control, (2) 37.5”x24” pallets, travels X-20.48”, Y-14.17”, Z-11.81”, W-360,000 positions in 0.001 degree increments, speeds to 13,000 RPM, BT30 spindle taper, 16-station ATC, coolant, chip tray, (220V/3PH/50-60HZ), s/n: 4400D063

- HYUNDAI SPT-V30T 4 axis CNC vertical machining center with HYUNDAI CNC control, 23.62”x14.96” table size, travels X-19.68”, Y-11.81”, Z-11.81”, W-360,000 positions in 0.001 degree increments, speeds to 8,000RPM, BT30 spindle taper, 14-station ATC, 5 HP spindle motor, chip tray, 220V/3PH/60HZ, s/n: 70D7033

CNC HIGH PRECISION GANG TYPE TURNING CENTER

- HYUNDAI WIA (2014) KIT-250 high precision CNC gang style turning center with FANUC i series CNC Control, 5.3” chuck, 12.6” swing over bed, 6.3” maximum turning diameter, 5.9” maximum turning length, 1.3” bar capacity, 1.65” spindle bore, travels X-9.8”, Z-7.9”, 4-station block tool, speeds to 7,000 RPM, 5 HP spindle motor, coolant, chip tray, (220V/3PH/60HZ), s/n: G3724-0448

CNC TURNING CENTER

- FORTUNE VTURN-26 CNC turning center with FANUC Oi-TB CNC control, KITAGAWA B-212 12" 3-jaw hydraulic chuck, 26.37" swing over bed, 14.56" maximum turning diameter, 24.40" centers, 3.38" spindle bore, travels X-18.94", Z-19.00", 12 station turret, speeds to 3500 RPM, hydraulic tailstock, coolant, chip conveyor, MISTBUSTER mist collector, (220V/3PH/50-60HZ), s/n: UC-3029

FORKLIFTS & PALLET TRUCKS

- RAYMOND (2008) 8400, 24v Electric Ride-On Pallet Truck with 6000lb capacity. Includes Battery and Oldham Charger. s/n 840-08-75998 (Unit# 2325)

- RAYMOND (2003) EZ-R40TT, 24v Electric Reach Truck with 4000lb capacity. Includes Battery and VPII Charger. s/n ET-D-03-12639 (Unit# 2396)

- RAYMOND (2005) C40-R40TT, 36v Electric Stand on Counterbalance Truck with 4000lb capacity. Includes Battery and GNB Charger. s/n R40-05-08765 (Unit# 2460)

- RAYMOND (2001) OPC30TT, 24v Order Picker Truck with 3000lb capacity. Includes Battery and VPII Charger. s/n EASi- 01-BC27682 (Unit# 2690)

- RAYMOND (2010) 8400, 24v Electric Ride-On Pallet Truck with 6000lb capacity. Includes Battery and GNB Charger. s/n 840-10-84375 (Unit# 2705)

- RAYMOND (2009) C35TT, 48v 3 Wheel Counterbalance Fork Lift with 3500lb capacity. Includes Battery and C&D Charger. s/n 440-09-10678 (Unit# 2711)

- RAYMOND (2011) 8400, 24v Electric Ride-On Pallet Truck with 8000lb capacity. Includes Battery and C&D Charger. s/n 840-11-89154 (Unit# 2712)

- RAYMOND (1998) R40TT, 36v Electric Reach Truck with 4000lb capacity. Includes Battery and Vulcan Charger. s/n EZ-A-98-10025 (Unit# 2716)

ALSO:

LARGE ASSORTMENT OF perishable tooling including carbide and conventional tooling, turning tools, live milling tool holders, CAT tool holders, machine tool accessories, CNC rotary table 4th axis units, inspection equipment, general machining and plant support assets, factory equipment and MORE!