AlliedOne Industrial Inc.

Major Late Model & High Precision Multi-Axis CNC Machining Event!

Date

Thursday, November 18, 2021

Start Time

9:00 AM EST

Inspection

BY APPOINTMENT ONLY. Please email [email protected] to arrange a date and time.

Removal

All assets must be removed no later than Wednesday, December 22 BY APPOINTMENT ONLY. Please email [email protected] to arrange.

Industry

Corporate Assets Inc. is pleased to announce its recent acquisition of the assets of AlliedOne Industrial Inc.—a high precision AS9100D / ISO 9001:2015 compliant facility specializing in the manufacturing of high tolerant precision aerospace components. This sale features a large quantity of late model CNC Multi-Axis Machining & Turning Equipment as NEW as 2021. Mark your calendars for this exceptional year end opportunity!

FEATURING: HAAS (APR 2021) UMC-1000SS high speed 5-axis CNC machining center (THIS MACHINE HAS ONLY 62 HOURS – $500K+ USD NEW); OKUMA (2018) SIMULTURN LU4000EX twin turret CNC 6-axis turning and live milling center (PURCHASED NEW IN 2018 FOR $525K); OKUMA (2018) MILLAC 761VII 4-axis CNC vertical machining center (PURCHASED NEW IN 2018 FOR $425K USD); HARDINGE (2011) GX1000 OSP high speed 4-axis CNC vertical machining center; NAKAMURA-TOME (2015 installed new 2016) SC-300IIMY-BB/SC-300L CNC turning and live milling center; NAKAMURA-TOME (2015) AS-200 CNC turning and live milling center; OKUMA (2011) GENOS L200E-M CNC turning and live milling center; NAKAMURA-TOME SC300 CNC turning and live milling center; NAKAMURA-TOME SC300 CNC turning and live milling center; NAKAMURA-TOME SC300 CNC turning and live milling center; NAKAMURA-TOME SC300II CNC turning and live milling center; NAKAMURA-TOME SC300 CNC turning and live milling center; NAKAMURA-TOME SC250 opposed spindle CNC turning and live milling center; NAKAMURA-TOME SC200 CNC turning and live milling center; NAKAMURA-TOME SC200 CNC turning and live milling center; NAKAMURA-TOME SC-200 CNC turning and live milling center; OKUMA (2008) ES-L8II-M CNC turning and live milling center; OKUMA (2006) HERITAGE ES-L10II CNC turning center; OKUMA (2006) ES-L8II CNC turning center; OKUMA CADET-M LNC8 CNC turning center; DOOSAN (2010) LYNX 220C CNC chucker; DOOSAN (2008) LYNX 220A CNC turning center; DOOSAN (2008) LYNX 220LC CNC turning center; MATSUURA (2004) H. PLUS-300 high speed twin pallet CNC horizontal machining center; HURCO (2007) VM1 CNC vertical machining center; HURCO (2006) VM1 CNC vertical machining center; LNS (2011) QLS 80 S2 quick load servo bar feeder; SMW SPAC.2200 SPACESAVER automatic all electric servo bar feeder; (5) LNS Q.L SERVO S3 quick load servo bar feeders; HAAS HA5C P1 single axis 5C collet indexer; KITAGAWA TECNARA (2006) TBX200BE03 4th axis CNC rotary indexer; ZEISS (JULY 2017) CONTURA 10/16/6 coordinate measuring machine w/ 39.37” x 62.99” table; GAGEMAKER MIC TRAC MT-3012-50 digital gage setting and part measuring system; MITUTOYO PH-3500 optical comparator; MITUTOYO PH-A14 optical comparator; MITUTOYO SJ-410 digital surface roughness tester; KBC (2006) TUM-1VS vertical milling machine; HARDINGE HC tool room precision automatic chucking lathe; SIC (2011) E8C153 dot peen type parts marking system; HYD-MECH S-20A automatic horizontal band saw; DOALL C916A horizontal band saw; LINCOLN ELECTRIC PRECISION TIG 375 digital TIG welder; LINCOLN ELECTRIC POWER MIG 210 MP digital portable MIG ARC welder; O’BRIEN (2017) MET-TRACK 2-ton capacity freestanding gantry crane system; KAESER (2017) SIGMA SK 20T 20hp screw type air compressor; KAESER (2006) SIGMA combination tank mounted air compressor; (10+) DIVERSITECH portable downdraft tables; (5+) AEROX mist extraction systems; SKY JACK (2017) SJ3226 electric scissor lift; NISSAN (2009) MCPL02A25LV 4000 lbs capacity LPG forklift; TENNANT (2018) 5680 electric walk behind type floor scrubber; MASSIVE OFFERING OF: 1000+ Lots of high precision tooling, inspection equipment & accessories, (500+) high speed tool holders, (10+) LISTA type cabinets, RAW MATERIAL BAR STOCK & INVENTORY, complete maintenance department, factory support equipment & MUCH MORE!

THE EXCLUSIVE RIGGER FOR THIS SALE IS:

NATIONAL RIGGING AND TRANSPORTATION

O: 905-788-1110 | C: 905-704-9011

Please contact: Darren Chapman

[email protected]

www.nationalrigging.com

5-AXIS HIGH SPEED CNC MACHINING CENTER

- HAAS (APR 2021) UMC-1000SS high speed 5-axis CNC machining center with HAAS touch screen CNC control, 25” diameter integrated 2-axis trunnion table with 1000 lbs max table capacity, travels X-40.00”, Y-25.00”, Z-25.00”, B-155 (-35 / +120) degrees, C-360 degrees, speeds to 15000 rpm, HSK-A63 spindle taper, 50 station ATC, RENISHAW touch probe system, coolant with cartridge type filtration, programmable coolant nozzle, chip conveyor, mist extractor, 220v/3ph/50-60hz, s/n 1180408 (ONLY 62 CUTTING HOURS)

MULTI-AXIS SIMULTANEOUS CNC TURNING CENTER & LIVE MILLING CENTER

- OKUMA (2018) SIMULTURN LU4000EX CNC 6-axis twin turret turning and live milling center with OKUMA OSP-P300LA CNC control, 4-axis simultaneous turning, 27.36” swing, 18.90” max turning diameter, 78.74” between centers, 4.41” spindle bore (big bore-factory installed option), travels XA-11.81”, ZA-84.33”, XB-7.68”, ZB-82.70”, Y-5.51”, C-360 degrees in 0.001 degree increments, speeds to 3000 rpm, KITAGAWA BB212 12.40” hydraulic 3-jaw chuck, KITAGAWA B-15 15” hydraulic 3-jaw chuck (new, never used, may be offered separately), V 12 station upper turret with live milling, milling spindle speeds to 6000 rpm, V 10 station lower turret with SMW AUTOBLOCK hydraulic steady rest, auto tow along tailstock, tool checker arm, 1000 psi high pressure coolant with MP SYSTEMS filtration, 220v/3ph/60hz, s/n 208714

4-AXIS CNC VERTICAL MACHINING CENTERS

- OKUMA (2018) MILLAC 761VII 4-axis CNC vertical machining center with OKUMA OSP-P300MA CNC control, table 70.87” x 28.35” with 4400 lbs max table capacity, travels X-60.63”, Y-29.92”, Z-25.98”, B-360 degrees, 33.86” max distance table top to spindle nose, speeds to 6000 rpm, CAT 50 spindle taper, 36 station ATC, TSUDAKOMA RWB-320R 12.59” diameter 4th axis rotary table with tailstock and trunnion attachment, 1000 psi high pressure thru spindle coolant with MP SYSTEMS filtration, 220v/3ph/60hz, s/n 209744

- HARDINGE (2011) GX1000 OSP high speed 4-axis CNC vertical machining center with OKUMA OSP-P200M CNC control, 21.25” x 44” table, travels X-40.16”, Y-21.00”, Z-21”, B-360 degrees, spindle speeds to 12000 rpm, CAT 40 spindle taper, 30 station ATC, TSUDAKOMA RNE-200R 4th axis rotary table with sub-table, tailstock and trunnion attachment (may be offered separately), high pressure thru spindle coolant with MP SYSTEMS chip filtration, LNS chip conveyor, AEROEX mist extractor (may be offered separately), 220v/3ph/60hz, s/n NVCB1B0032

CNC TURNING & LIVE MILLING CENTERS

- NAKAMURA-TOME (2015 installed new 2016) SC-300IIMY-BB/SC-300L CNC turning and live milling center with NAKAMURA FANUC OiT-D CNC control, 28.07” distance between centers, 14.73” max turning diameter, 23.62” max turning length, upgraded 3.50” bar capacity, travels X-8.80”, Z-25”, Y-4.72”, speeds to 2500 rpm, KITAGAWA B-212A08 12” hydraulic 3-jaw chuck, half index 24-station turret with live milling, milling spindle speeds to 3600 rpm, hydraulic programmable tailstock, parts catcher, 1000 psi high pressure coolant, chip conveyor, AEROEX mist extractor, 200-220v/3ph/50-60hz, s/n S312602

- NAKAMURA-TOME (2015) AS-200 CNC turning and live milling center with FANUC 21i-TB CNC control, 17.00” max turning diameter, 12.99” max turning length, travels X-10.90”, Z-14.37”, Y-3.22”, C-360 degrees, speeds to 4500 rpm, KITAGAWA 8” hydraulic 3-jaw chuck, 12-station turret with live milling, milling spindle speeds to 6000 rpm, hydraulic programmable tailstock, parts catcher, coolant, chip conveyor, AEROEX mist extractor, 200-220v/3ph/50-60hz, s/n KS202209

- OKUMA (2011) GENOS L200E-M CNC turning and live milling center with OKUMA OSP-P200L-R CNC control, 17.72” swing, 7.87” max turning diameter, 14.96” max turning length, 2.59” spindle bore, travels X-6.50”, Z-15.75” speeds to 3000 rpm, collet chuck w/ collets, KITAGAWA B-208A6 8.25” hydraulic 3-jaw chuck (may be offered separately), VDI 12-station turret w/ live milling, milling spindle speeds to 6000 rpm, hydraulic tailstock, parts catcher, high pressure coolant, chip conveyor, 220v/3ph/50-60hz, s/n MF 492 (3)

- NAKAMURA-TOME SC300 CNC turning and live milling center with FANUC 21i-TB CNC control, 22.04” swing, 13.77” max turning diameter, 23.62” max turning length, travels X-8.75”, Z-25.00”, speeds to 3500 rpm, KITAGAWA 12” hydraulic 3-jaw chuck, 12-station turret with live milling, milling spindle speeds to 3600 rpm, hydraulic programmable tailstock, parts catcher, coolant, chip conveyor, AEROEX mist extractor, 200-220v/3ph/50-60hz, s/n S310703

- NAKAMURA-TOME SC300 CNC turning and live milling center with FANUC 21i-TB CNC control, 22.04” swing, 13.77” max turning diameter, 23.62” max turning length, travels X-8.75”, Z-25.00”, speeds to 3500 rpm, KITAGAWA 12” hydraulic 3-jaw chuck, 12-station turret with live milling, milling spindle speeds to 3600 rpm, hydraulic programmable tailstock, parts catcher, coolant, chip conveyor, AEROEX mist extractor, 200-220v/3ph/50-60hz, s/n S309901

- NAKAMURA-TOME SC300 CNC turning and live milling center with FANUC 21i-TB CNC control, 22.04” swing, 13.77” max turning diameter, 23.62” max turning length, travels X-8.75”, Z-25.00”, speeds to 3500 rpm, KITAGAWA 12” hydraulic 3-jaw chuck, 12-station turret with live milling, milling spindle speeds to 3600 rpm, hydraulic programmable tailstock, parts catcher, coolant, chip conveyor, AEROEX mist extractor, 200-220v/3ph/50-60hz, s/n S309702

- NAKAMURA-TOME SC300II CNC turning and live milling center with FANUC 21i-TB CNC control, 22.04” swing, 13.77” max turning diameter, 23.62” max turning length, travels X-8.75”, Z-25.00”, speeds to 3500 rpm, KITAGAWA 12” hydraulic 3-jaw chuck, 12-station turret with live milling, milling spindle speeds to 3600 rpm, hydraulic programmable tailstock, parts catcher, coolant, chip conveyor, AEROEX mist extractor, 200-220v/3ph/50-60hz, s/n 309105

- NAKAMURA-TOME SC300 CNC turning and live milling center with FANUC 21i-TB CNC control, 22.04” swing, 13.77” max turning diameter, 23.62” max turning length, travels X-8.75”, Z-25.00”, speeds to 3500 rpm, KITAGAWA 12” hydraulic 3-jaw chuck, 12-station turret with live milling, milling spindle speeds to 3600 rpm, hydraulic programmable tailstock, parts catcher, coolant, chip conveyor, AEROEX mist extractor, 200-220v/3ph/50-60hz, s/n S301802

- NAKAMURA-TOME SC250 opposed spindle CNC turning and live milling center with FANUC 18i-T CNC control, 11.80” max turning diameter, 19.70” max turning length, travels X-6.98”, Z-19.69”, main spindle speeds to 4500 rpm, sub spindle speeds to 5000 rpm, KITAGAWA BB-08 8” hydraulic 3-jaw main spindle chuck, KITAGAWA B-206 6.5” hydraulic 3-jaw sub spindle chuck, 12-station turret with live milling, milling spindle speeds to 3600 rpm, parts catcher, coolant, chip conveyor, AEROEX mist extractor, 200-220v/3ph/50-60hz, s/n S204405

- NAKAMURA-TOME SC200 CNC turning and live milling center with FANUC 21i-TB CNC control, 17.00” max turning diameter, 12.99” max turning length, travels X-10.27”, Z-14.37”, speeds to 4500 rpm, KITAGAWA BB-208 8.25” hydraulic 3-jaw chuck, 12-station turret with live milling, milling spindle speeds to 6000 rpm, hydraulic programmable tailstock, parts catcher, coolant, chip conveyor, AEROEX mist extractor, 200-220v/3ph/50-60hz, s/n P202604

- NAKAMURA-TOME SC200 CNC turning and live milling center with FANUC 21i-TB CNC control, 17.00” max turning diameter, 12.99” max turning length, travels X-10.27”, Z-14.37”, speeds to 4500 rpm, MICROCENTRIC CB-65ND hydraulic collet chuck, 12-station turret with live milling, milling spindle speeds to 6000 rpm, hydraulic programmable tailstock, parts catcher, coolant, chip conveyor, AEROEX mist extractor, 200-220v/3ph/50-60hz, s/n P200810

- NAKAMURA-TOME SC-200 CNC turning and live milling center with FANUC 21i-TB CNC control, 17.00” max turning diameter, 12.99” max turning length, travels X-10.27”, Z-14.37”, speeds to 4500 rpm, MICROCENTRIC CB-65ND hydraulic collet chuck, 12-station turret with live milling, milling spindle speeds to 6000 rpm, hydraulic programmable tailstock, parts catcher, coolant, chip conveyor, AEROEX mist extractor, 200-220v/3ph/50-60hz, s/n P200804

- OKUMA (2008) ES-L8II-M CNC turning and live milling center with OKUMA OSP-P200L-R CNC control, 17.72” swing, 7.87” max turning diameter, 14.96” max turning length, 2.59” spindle bore, speeds to 3000 rpm, KITAGAWA B-208A6 8.25” hydraulic 3-jaw chuck, collet chuck with collets (may be offered separately), VDI 12-station turret with live milling, milling spindle speeds to 6000 rpm, hydraulic tailstock, parts catcher, chip conveyor, 220v/3ph/60hz, s/n ME289 (1)

CNC TURNING CENTERS

- OKUMA (2006) HERITAGE ES-L10II CNC turning center with OKUMA OSP-U10L CNC control, 20.47” swing, 12.20” max turning diameter, 19.60” max turning length, 3.15” spindle bore, travels X-8.66”, Z-20.47”, speeds to 3000 rpm, KITAGAWA B-210A8 10” hydraulic 3-jaw chuck, collet chuck with collets (may be offered separately), 12-station turret, hydraulic tailstock, high pressure coolant, chip conveyor, 220v/3ph/60hz, s/n P0328 (4)

- OKUMA (2006) ES-L8II CNC turning center with OKUMA OSP-U10L CNC control, 17.72” swing, 10.63” max turning diameter, 19.60” max turning length, 2.60” spindle bore, travels X-6.10”, Z-20.47”, speeds to 3000 rpm, KITAGAWA B-208A6 8.25” hydraulic 3-jaw chuck, collet chuck with collets (may be offered separately, 8-station turret, hydraulic tailstock, parts catcher, chip conveyor, 220v/3ph/60hz, s/n C1884 (2)

- OKUMA CADET-M LNC8 CNC turning center with OKUMA OSP5000L-G CNC control, 15.74” swing, 9.84” max turning diameter, 15.00” max turning length, 2.20” spindle bore, travels X-5.12”, Z-19.70”, speeds to 4200 rpm, collet chuck with collets, KITAGAWA B-210 10” hydraulic 3-jaw chuck (may be offered separately), 10-station turret, hydraulic tailstock, tool checker arm, coolant, chip conveyor, 480-220v/3ph/60hz, s/n D899 (5)

- DOOSAN (2010) LYNX 220C CNC chucker with FANUC i-SERIES CNC control, 12.60” max turning diameter, 12.70” max turning length, travels X-6.90”, Z-13.00”, speeds to 4000 rpm, KITAGAWA 6.5” hydraulic 3-jaw chuck, 12-station turret, tool checker arm, parts catcher, coolant, chip conveyor, AEROEX mist extractor, 200-220v/3ph/50-60hz, s/n L2204152

- DOOSAN (2008) LYNX 220A CNC turning center with FANUC OiT-D CNC control, 20.10” swing, 12.60” max turning diameter, 12.70” max turning length, travels X-6.90”, Z-12.60”, speeds to 6000 rpm, CAH-06 4.5” hydraulic 3-jaw chuck, 12-station turret, hydraulic programmable tailstock, tool checker arm, parts catcher, coolant, chip conveyor, AEROEX mist extractor, 200-220v/3ph/50-60hz, s/n L2203446

- DOOSAN (2008) LYNX 220LC CNC turning center with FANUC Oi-TC CNC control, 20.10” swing, 12.60” max turning diameter, 20.70” max turning length, travels X-6.90”, Z-21.70”, speeds to 4000 rpm, KITAGAWA B-210 210” hydraulic 3-jaw chuck, 12-station turret, hydraulic programmable tailstock, tool checker arm, coolant, chip conveyor, AEROEX mist extractor, 200-220v/3ph/50-60hz, s/n L2202916

CNC GANTRY TYPE HIGH SPEED VERTICAL MACHINING CENTERS

- KAO MING (2013) KMC-318HIS, CNC double column high speed vertical machining center with FANUC SERIES 31i-MODEL B CNC control, 65” x 118” T-slot table, travels: X-127”, Y-66”, Z-33”, speeds to 10,000 RPM, CAT 50 taper, 60 station ATC, spindle oil chiller, chip conveyor, through spindle coolant, s/n 313HS003 (Located in Scarborough, ON)

- FIRST (2007) MCV-2000, CNC high speed bridge type vertical machining center with FANUC SERIES 18i-MB CNC control, 39.37” x 86.5” T-slot table, travels: X-80”, Y-44”, Z-27”, speeds to 15,000 RPM, BT40 taper, 30 station ATC, spindle oil chiller, chip auger and conveyor, s/n 60600042 (Located in Scarborough, ON)

CNC TABLE TYPE HORIZONTAL BORING MILL

- FORTWORTH (2012) HB-800A, CNC table type horizontal boring mill with 39.37” x 39.37” T-slot rotary table, Travels: X-78”, Y-47”, Z-47”, FANUC SERIES Oi-MD CNC control, 6000 RPM, CAT 50 taper, 60 ATC, oil temperature control unit, chip conveyor, thru spindle coolant, s/n 8027 (Located in Scarborough, ON)

TWIN PALLET CNC HORIZONTAL MACHINING CENTER

- MATSUURA (2004) H. PLUS-300 twin pallet CNC horizontal machining center with MATSUURA G-TECH 16i (FANUC 16i) CNC control, 11.81” x 11.81” pallets, travels X-19.68”, Y-19.68”, Z-19.68”, B-360 degrees, speeds to 15000 rpm, BT 40 spindle taper, 51 station ATC, high pressure thru spindle coolant, chip conveyor, AEROEX REX mist extractor (may be offered separately), 200-220v/3ph/50-60hz, s/n 15922

CNC VERTICAL MACHINING CENTERS

- HURCO (2007) VM1 CNC vertical machining center with HURCO MAX CNC control, 14” x 30” table with 750 lbs max table capacity, travels X-26”, Y-14”, Z-18”, speeds to 8000 rpm, CAT 40 spindle taper, 20 station ATC, coolant chip auger, 230v/3ph/60hz, s/n H-V12002

- HURCO (2006) VM1 CNC vertical machining center with HURCO MAX CNC control, 14” x 30” table with 750 lbs max table capacity, travels X-26”, Y-14”, Z-18”, speeds to 8000 rpm, CAT 40 spindle taper, 20 station ATC, coolant chip auger, 230v/3ph/60hz, s/n H-V11870

SERVO BAR FEEDERS

- LNS (2011) QLS 80 S2 quick load servo bar feeder, 200-480v/3ph/50-60hz, s/n 27014101

- SMW SPAC.2200 SPACESAVER automatic all electric servo bar feeder, s/n 18-526/01/2006

- LNS Q.L SERVO S3 quick load servo bar feeder, 220v/3ph/50-60hz, s/n 303204

- LNS Q.L SERVO S3 quick load servo bar feeder, 220v/3ph/50-60hz, s/n 302980

- LNS Q.L SERVO S3 quick load servo bar feeder, 220v/3ph/50-60hz, s/n 18002100387

- LNS Q.L SERVO S3 quick load servo bar feeder, 220v/3ph/50-60hz, s/n 302834

- LNS Q.L SERVO S3 quick load servo bar feeder, 220v/3ph/50-60hz, s/n 302835

CNC MACHINE TOOL ACCESSORIES

- HAAS HA5C P1 single axis 5C collet indexer with HAAS brushless programmable control, 360 degree indexing in 0.001-degree increments, 4” center height, s/n 511366

- KITAGAWA TECNARA (2006) TBX200BE03 4th axis CNC rotary indexer with 8” table, 2.75” bore, quick connect couplers and cables, s/n 060268

CNC ROUTER

- KOMO (2015) SOLUTION XL-524 high speed CNC router with FANUC PANELi CNC control with integrated PC, 5' X 24' table, travels X – 288”, Y – 60”, Z – 18”, speeds to 24,000 RPM, 23 HP, 12 station ATC, HSK-63F spindle, 4 pole electro-spindle, liquid cooled spindle, interpolating C-axis, single head mist, automatic lubrication system, s/n 01202-14 (Located in Granby, QC)

Q.C. & Inspection Equipment

- ZEISS (JULY 2017) CONTURA 10/16/6 coordinate measuring machine with CALYPSO 2017 V6.4.08 WINDOWS based control and data acquisition PC, 39.37” x 62.99” x 23.62” measuring envelope, ZEISS VAST XT scanning probe, 7 station automatic head changer, joystick pendant control, s/n 731707531433

- GAGEMAKER MIC TRAC MT-3012-50 digital gage setting and part measuring system with 0.00005” resolution, GAGEMAKER QCC SYSTEM DRO, s/n K7J00

- MITUTOYO PH-3500 optical comparator with 15” screen, MITOTOYO QM-DATA 200 DRO, s/n 4N0111

- MITUTOYO PH-A14 optical comparator with 14” screen, MITOTOYO QM-DATA 200 DRO, s/n 601024

- MITUTOYO QMH-600 24” digital height gauge, s/n 0000089

- MITUTOYO SJ-410 digital surface roughness tester with probe, heavy duty column stand, thermal results printer, s/n 00136607

- WILSON 3JR ROCKWELL analog hardness tester with stand, s/n 1067

- MITUTOYO 36” x 48” x 6” black granite surface plate with stand, s/n n/a

- MITUTOYO 24” x 36” x 4” black granite surface plate with stand, s/n n/a

CONVENTIONAL MACHINE TOOLS

- KBC (2006) TUM-1VS vertical milling machine with 9” x 49” table, R8 spindle taper, speeds to 4200 rpm infinitely variable, 3 hp, power table feed, NEWALL 2-axis DRO, coolant, 575v/3ph/60hz, s/n 062129

- HARDINGE HC tool room precision automatic chucking lathe with 13” swing over bed, 13” max distance spindle to turret face, speeds to 3000 rpm in (3) ranges, 5C collet chuck with lever closer and complement of collets, 5” 4-jaw chuck, 5” 3-jaw chuck, HARDINGE CT-A automatic threading attachment, variable speed carriage, coolant, 200v/3ph/60hz, s/n HC-5128-T

- DECKEL tool and cutter grinder with stand, collets and accessories, 120v/1ph/60hz, s/n S0E/65-194

- JU YAO MODEL 12 bench type tool and cutter grinder, 120v/1ph/60hz, s/n 100840

- ROBEN GS-25 bench type precision drill grinder, 120v/1ph/60hz, s/n 08081576101

- STM DM213 bench type precision drill grinder, 120v/1ph/60hz, s/n n/a

- SIC (2011) E8C153 dot peen type parts marking system with SIC E8 digital programmable control, SIC 3” rotary table suited for cylindrical parts marking, 120v/1ph/60hz, s/n 85330

SAWS

- HYD-MECH S-20A automatic horizontal band saw with HYD-MECH PLC 100 digital programmable control, 13” x 18” capacity, 5 hp, auto feed, hydraulic shuttle vise, hydraulic bundling vise, coolant, chip auger, 240v/3ph/60hz, s/n 81197323

- DOALL C916A horizontal band saw with 9” x 16” capacity, 2 hp drive motor, hydraulic elevation, spring balanced head, coolant, manual clamping, roller in-feed conveyor, 230v/3ph/60hz, s/n 547-06282

- ROUBAX VERTICUT 115-A vertical roll-in band saw with 10” capacity, ¾ hp, 110v/1ph/60hz, s/n 417

MAINTENANCE SHOP

- LINCOLN ELECTRIC PRECISION TIG 375 digital TIG welder with cables and gun, s/n U1020117465

- LINCOLN ELECTRIC POWER MIG 210 MP digital portable MIG ARC welder with cables and gun, s/n M3161200857

- CANOX MIG MATIC 250 portable MIG ARC welder with cables and gun, s/n HD701062

- STRONGARM MODEL 120A 20-ton capacity hydraulic H-frame shop press, s/n n/a

- JET JDP-17F 17” heavy duty floor type drill press with 13.75” diameter table, 1 hp, 120v/1ph/60hz, s/n 321633

- JET JDP-13 13.5” heavy duty bench type drill press with 12” diameter table, 1 hp, 120v/1ph/60hz, s/n 301409

- EMPIRE EF-2436 floor type abrasive blasting cabinet with media recovery, 120v/1ph/60hz, s/n 24624

- WORKFORCE 6” double end bench grinder, 120v/1ph/60hz, s/n 006643

- JET 6” double end pedestal grinder, 120v/1ph/60hz, s/n 1500034

- PALMGREEN 81061B bench type combination 2” belt, 6” disc sander with 1/3 hp, 120v/1ph/60hz, s/n 201206

- TRADE MAX QUICK TAP flex arm type pneumatic tapping arm, s/n n/a

FACTORY EQUIPMENT

- O’BRIEN (2017) MET-TRACK 2-ton capacity freestanding gantry crane system with 2-ton capacity electric chain hoist, approx. 25’ span, 15’ height under the hook, free standing gantry system with 38’ runway and uprights, all bolted construction, s/n 06367-01

- KAESER (2017) SIGMA SK 20T 20hp screw type air compressor with 88 cfm @ 125 psig capacity screw type air compressor, approx. 18,900 hours recorded on meter at the time of listing, 575-332v/3ph/60hz, s/n 1002

- KAESER (2006) SIGMA combination tank mounted screw type air compressor – refrigerated air dryer with SIGMA SM8 7.5hp, 28 cfm @ 125 psig capacity screw type air compressor, SIGMA TA8 refrigerated air dryer, 575v/3ph/60hz, s/n 1006

- HANNAN 420T 24” x 36” fully automatic vacuum forming skin packaging machine, 200-220v/3ph/50-60hz, s/n 7551

- VIDEOJET 1520 ink jet coding and parts marking machine with print head, fixture and cart, 120v/1ph/60hz, s/n 18261052C22ZH

- DIVERSITECH 36” x 72” single station downdraft table, 120v/1ph/60hz, s/n n/a

- DIVERSITECH 36” x 48” dual station downdraft table, 120v/1ph/60hz, s/n n/a

- DIVERSITECH 36” x 36” dual station downdraft table, 120v/1ph/60hz, s/n n/a

- (7) DIVERSITECH 30” x 30” portable downdraft tables, 120v/1ph/60hz, s/n n/a

- DIVERSITECH portable snorkel type welding fume extractor, 120v/1ph/60hz, s/n n/a

- AEROEX REX 400 overhead mist extractor with 1 hp, 220-460v/3ph/60hz, s/n n/a

- (2) AEROEX REX 500 overhead mist extractors with 1/2 hp, 220-460v/3ph/60hz, s/n n/a; n/a

- AEROEX mist extractor with ductwork, s/n n/a (OKUMA turning centers)

VEHICLES & ROLLING STOCK

- AUDI (2013) A4 sedan with 2.0T automatic engine, QUATTRO AWD, S-LINE sport package, keyless entry, push start, sunroof, ALCANTARA leather/suede heated seats, power memory driver’s seat, navigation, bluetooth audio, audi R19 summer rims, R18 winter rims included, 112,000KM (recorded at time of listing), vin: WAUFFCFL5DN035974

- NISSAN (2019) NV200SV light duty cargo van with 2L L4 gas engine, automatic, front wheel drive, keyless entry, cargo divider, approx. 65,500KM (recorded at time of listing), VIN: 3N6CM0KN1KK702203

- SKY JACK (2017) SJ3226 electric scissor lift with 500 lbs lifting capacity, 26’ max vertical reach, built in 24v on board battery charger, s/n 27035532

- NISSAN (2009) MCPL02A25LV 4000 lbs capacity LPG forklift with 187” max vertical reach, 3-stage high visibility mast, side shift, cushion tires, approx. 3045 hours recorded on meter at the time of listing, digital weigh scale, s/n CPL02-9P0199

- TENNANT (2018) 5680 electric walk behind type floor scrubber with 36v automatic battery charger, only approx. 45 hours recorded on meter at the time of listing, s/n 5680-10746745

ALSO:

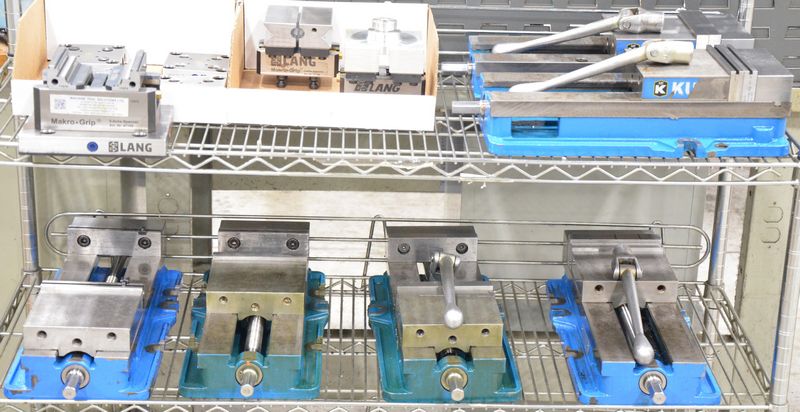

- HUGE selection of machine tool accessories including VERTEX 10” indexing rotary table, STM dividing head with plates and tailstock, precision setup blocks, parallels, KURT late model machine vises; TOOL CRIB including but not limited to perishable tooling, drills, conventional and carbide end mills, taps, reamers, carbide insert cutters, carbide insert boring bars, SANDVIK anti vibration carbide insert spade drills, carbide inserts; LARGE SELECTION OF TOOL HOLDERS comprising HSK-A63, CAT 40, CAT 50, CAPTO, VDI live milling holders; COMPLETE Q.C. DEPARTMENT featuring very late model MITUTOYO digital height gauges, digital bore gauges, SUNNEN gauge setting fixtures, MITUTOYO digital outside micrometers, depth micrometers and Vernier calipers, MITUTOYO surface roughness testers, plug gauges, pin gauges, block gauges, portable hardness testers; (25+) LISTA & ROUSSEAU tool cabinets; maintenance department including tools, hand tools, power tools and more tools, cabinets with spares, parts and supplies; shop and front offices featuring very late model designer executive furniture, board room with leather chairs, computers business machines and MUCH MORE!