Dietron Tool & Die Inc.

50,000+ Sq. Ft. Tool & Die Facility

Date

Tuesday, May 10, 2022

Start Time

9:30 AM EDT

Inspection

Monday, May 9 from 9 a.m. to 5 p.m. or email [email protected] to arrange an alternate date and time.

Removal

All assets must be removed no later than Friday, June 24 by appointment only. Rigging details to follow.

Industry

Corporate Assets Inc. is pleased to announce the upcoming auction of Dietron Tool & Die Inc.—a large capacity & late model CNC Machining and Stamping facility. The sale is scheduled to take place Live ONSITE with simultaneous WEBCAST at 9:30 AM EDT on May 10th, 2022. Mark your calendars for this exceptional event of late model & well-maintained equipment that is not to be missed!

A brief summary of assets are as follows: BLISS SE2-800-132-60, 800 ton straight side stamping press; BLISS SE4-600-108X72, 600 ton straight side stamping press w/ roll-in bolster; CLEARING S4-500-132-72, 500 ton straight side stamping press; PARPAS (2016) ROLLER, high speed 5-AXIS CNC bridge type machining center; TAKUMI (2014) H16, high speed CNC bridge type vertical machining center; TAKUMI (2015) H13, high speed CNC bridge type vertical machining center; FPT (2001) SIRIO M, 4 + 1 Axis CNC floor type horizontal boring mill w/ (1) straight milling head & (1) CNC controlled universal head; OKUMA MCV-AII 20x40, CNC bridge type vertical machining center w/ 59” x 149” table; DAH-LIH DL-MCV2100, CNC vertical machining center; BODOR (2017) F1530, 800W CNC fibre laser w/ 60” x 120” table; SODICK AQ537L, CNC wire type EDM; SODICK AQ535L, CNC wire type EDM; MITUTOYO BRIGHT BRT 910, CMM; BROWN AND SHARPE DEA SCIROCCO 15-10-09, CMM; HYDMECH H-20, heavy-duty automatic horizontal saw; MARVEL SERIES 81A, tilting frame vertical saw; (4) MAS VO50, 6’ way type radial arm drills; (5) FIRST LC-185VS, vertical milling machines; (2) FORWARD S-243, geared head drills; RUNMASTER RUN-410X1000, engine lathe; JAESPA AS6M, vertical bandsaw; TOS FGS32, heavy duty universal milling machine; (2) PROTH PSGS3060AH, hydraulic surface grinder; PROTH PSGC50100AHR-B, hydraulic surface grinder; (4) KENT KGS-200, surface grinders; (2) CHEVALIER FSG-618M, surface grinders; SUNNEN MBB-1600, honing machine; ANCHOR LAMINA EDS-40T-PUP, hydraulic die setter; AMERICAN STEEL LINE 10,000lb motorized mandrel type uncoiler; ROWE C4-30/8J, servo straightener/feeder; BWM servo straightener/feeder; ATLAS COPCO (2014) GA22VSD+FF, 30HP air compressor; ATLAS COPCO GA37FF, 50 HP air compressor; (4) SOS 10 ton x 40’ overhead bridge cranes; (3) SOS 5 ton x 40’ overhead bridge cranes; (2) P&H 20 ton x 33’ overhead bridge cranes; CATERPILLAR T300, 30,000LB LPG forklift; HANSFORD 1021, 20 ton portable die handler; TOYOTA 8FGCU30, 5,000lb LPG forklift; SKYJACK SJIII 3220, electric scissor lift; HUGE OFFERING OF precision inspection & testing equipment, high end perishable tooling, machine tool accessories, welding equipment & accessories, lifting equipment & accessories, LISTA type tool cabinets, general production support related assets, factory support equipment, office furniture & equipment and MUCH MORE!

THE EXCLUSIVE RIGGER FOR THIS SALE IS:

National Rigging and Transportation

Darren Chapman

O: 905-788-1110 • C: 905-704-9011

[email protected]

*For everyone’s safety removal at this site is conducted strictly by appointment only. All machinery buyers must contact [email protected] to set their pick-up appointments upon payment in full.

HIGH-SPEED 5-AXIS GANTRY TYPE CNC MACHINING CENTER

- PARPAS (2016) OMV ROLLER high speed 5-axis gantry type CNC machining center with HEIDENHAIN ITNC-530 CNC control, 39.37" x 39.37" table, 7,700 lbs maximum table capacity, travels: X-47.24", Y-70.86", Z-39.34", A - (+/-)110 degrees, C - 360 degrees with 0.001 degree positioning accuracy, 52" distance between columns, 29.52” max distance from spindle nose to tabletop, 1377 ipm max feed rate with 0.000039” accuracy, HSK-A63 spindle taper, PARPAS MTS-29.92 LONG LIFE high-speed spindle with speeds to 20,000 rpm, 38/50 hp spindle motor, 735 psi high pressure through spindle coolant with paper filtration, 42 station ATC, M&H HEXAGON RWP38 radio touch probe with receiver and integrated PC-DMIS on machine CMM measuring software, BLUM HEXAGON LTS35 laser tool setter, dual chip auger and conveyor, automatic temperature compensation, 480v/3ph/60hz, s/n: 711R/15

HIGH-SPEED BRIDGE-TYPE CNC VERTICAL MACHINING CENTERS

- TAKUMI (2015) H13 high-speed bridge type CNC vertical machining center with FANUC SERIES 31i-MB CNC control, 35.40" x 55.10" table, 7,700 lbs maximum table capacity, travels: X-35.40", Y-51.20", Z-27.60", 59" distance between columns, 7.9”-35.40” distance from spindle nose to tabletop, 1181 ipm max feed rate, CAT 50 spindle taper, spindle speeds to 10,000 rpm direct drive, 30/35 hp spindle motor, 20 station ATC, RENISHAW OMI-2T touch probe system, 300 psi high pressure through spindle coolant with paper filtration, chip conveyor, 220v/3ph/50-60hz, s/n H13187

- TAKUMI (2014) H16 high speed bridge type CNC vertical machining center with HEIDENHAIN ITNC-530 CNC control, 74.80" x 51.20" table, 13,250 lbs maximum table capacity, travels: X-63.00", Y-51.20", Z-27.60", 59" distance between columns, 7.9”-35.40” distance from spindle nose to table top, 1181 ipm max feed rate, CAT 50 spindle taper, spindle speeds to 10,000 rpm direct drive, 30/35 hp spindle motor, 32 station ATC, RENISHAW OMI-2T touch probe system, 300 psi high pressure through spindle coolant with paper filtration, chip conveyor, 380v/3ph/60hz, s/n: H16237

DOUBLE COLUMN CNC VERTICAL MACHINING CENTER

- OKUMA MCV-AII 20x40 double column CNC vertical machining center with OKUMA OSP7000M CNC control, 59.06" x 161.42" table with 26,400 lbs maximum table loading capacity, travels: X-157.48", Y-78.74", Z-17.72", 10 position power elevating cross rail with 45.28" travel, 80.71” distance between columns, 60.24” max distance from spindle nose to table top, CAT50 spindle taper, spindle speeds to 6000 rpm, 25/30 hp spindle motor, 24-station ATC, coolant, manual right angle head, 220-480v/3ph/60hz, s/n: 0905.2258

CNC FLOOR-TYPE HORIZONTAL BORING & MILLING MACHINE

- FPT (2001) SIRIO M high speed travelling column CNC horizontal boring and milling machine with HEIDENHAIN TNC 426/430M CNC control, travels: X-236.22”, Y-78.74”, Z-47.24”, CAT 50 spindle taper, spindle speeds to 5000 rpm, 40-station ATC, dual station head storage cradle with (1) straight head and (1) CNC controlled universal head, 236.22" x 78.84" x 12" t-slot floor plate and (2) 39.37” x 98.42” x 47.24” t-slot angle plates (may be sold separately), through spindle coolant, chiller, chip conveyor, 380v/3ph/60hz, s/n: LM0601077

CNC VERTICAL MACHINING CENTER

- DAH-LIH DL-MCV2100 CNC vertical machining center with FANUC SERIES O-M CNC control, 32” x 90” table, travels: X-86.70”, Y-34.20”, Z-29.90”, CAT50 spindle taper, spindle speeds to 6000 rpm, 25/30 hp spindle motor, 32-station ATC, coolant, chip auger, chip tray, 220v/3ph/60hz, s/n: 2100195

WIRE-TYPE CNC EDMS

- SODICK (2005) AQ537L wire-type CNC EDM with SODICK LQ33W CNC control, 28" x 43" tank, 13.77” max workpiece height, travels: X-22.80”, Y-14.80”, Z-14.00”, dielectric tank with pumps and filtration, 220v/3ph/60hz, s/n: 0067

- SODICK (2004) AQ535L wire-type CNC EDM with SODICK LQ33W CNC control, 28" x 43" tank, 10.62” max workpiece height, travels: X-21.65”, Y-13.77”, Z-11.81”, dielectric tank with pumps and filtration, 220v/3ph/60hz, s/n: 1020

STAMPING PRESSES & FEED EQUIPMENT

- BLISS SE2-800-132-60 800TON capacity straight side stamping press with 132"x60" bolster, 24" stroke, 69" shut height, 15" slide adjustment, 14SPM, 43"X40" side windows, upgraded lube system, push button and t-stand control, 575v/3ph/60hz, s/n: CN-2766

- BLISS SE4-600-108X72 600TON capacity straight side stamping press with 108"x72" side rolling roll-in bolster, 20" stroke, 53.5" shut height, push button and t-stand control, 575v/3ph/60hz, s/n: N/A

- CLEARING S4-500-132-72 500TON capacity straight side stamping press with 132"x72" bolster, 20" stroke, 40" shut height, 10" slide adjustment, 15spm, upgraded SIEMENS HMI digital die monitor system, push button and t-stand control, 575v/3ph/60hz, s/n: 53-18002

- AMERICAN STEEL LINE (1987)1000 10,000LB capacity motorized uncoiler with 40" maximum coil width, 60" maximum coil diameter, hydraulic shuttle car, hydraulic expanding mandrel, 575v/3ph/60hz, s/n: 8074

- ROWE C4-30/8J servo straightener/feeder with 0.020" minimum material thickness, 0.150" maximum material thickness, 30" maximum material width, 575v/3ph/60hz, s/n: 23366

- BWM servo straightener/feeder with 0.25" maximum material thickness, 24" maximum material width, 575v/3ph/60hz, s/n: N/A

- MFG UNKNOWN straightener/feeder with 24" maximum material width, upgraded digital VFD, 575v/3ph/60hz, s/n: N/A

- ANCHOR LAMINA EDS-40T-PUP hydraulic die setter with E300 digital microprocessor control, (4) hydraulic lift cylinders with retractable hose reels, portable cart-mounted frame, 575v/3ph/60hz, s/n: 1063

- HANSFORD 1021 portable die handler with 20TON capacity, 64"x30" platen, maximum 3000LB workpiece weight, 8" shuck height, 28" open height, 360 degree top platen rotation, 575v/3ph/60hz, s/n: 659

CNC FIBRE LASER

- BODOR (2017) F1530 800W CNC fibre laser with BODOR PRO 12.73 CNC control, 60"x120" table, MAXPHOTONICS 800-watt capacity laser source, BODOR GENIU auto focus laser cutting head, S&A CWFL-1000 chiller, fume extractor with blower, 380v/3ph/60hz, s/n: n/a

FABRICATION & WELDING

- HOBART R-400 portable arc welder with cables and gun, s/n: 16RT-5841

- LINCOLN ELECTRIC 180C POWERMIG portable MIG welder with cart, cables, and gun, s/n: M3090307401

- THERMAL DYNAMICS 1750WXL portable plasma cutter, s/n: N/A (not in service)

- ACKLANDS AK-MATIC 1200 portable MIG welder with cables and gun, s/n: JJ467385

- LINCOLN ELECTRIC PRECISIONTIG 225 digital TIG welder with cables and gun, s/n: U1090702908

CONVENTIONAL MACHINE TOOLS

- HYDMECH H-20 heavy-duty automatic horizontal bandsaw with HYDMECH PLC 100 programmable control, 20" x 20" maximum workpiece size, power feed, hydraulic shuttle vise, coolant, 575v/3ph/60hz, s/n: C06950401H

- MARVEL SERIES 81A tilting frame vertical bandsaw with 18" throat, 24" maximum workpiece height, coolant, hydraulic clamping, 575v/3ph/60hz, s/n: E-304588

- (2) E-R MAIRER MFG KM1012 10" capacity vertical roll-in bandsaws, 120v/1ph/60hz, s/n: 63894; 05885

- JAESPA AS6M vertical bandsaw with 24" throat, 12" maximum workpiece height, 26" x 26" sliding table, blade welder/grinder, 575v/3ph/60hz, s/n: 14435.88

- RUNMASTER RUN-410X1000 engine lathe with 16" swing, 39.37" between centers, 2.5" spindle bore, 10" 3-jaw chuck, speeds to 2000 rpm, IN/MM threading, quick change tool post, 575v/3ph/60hz, s/n: 901007

- MAS VO50 6' way-type radial arm drill with speeds to 2500 rpm, pre-select, 30" x 40" x 19.5" box table, 575v/3ph/60hz, s/n: 3528

- (2) MAS VO50 6' way-type radial arm drills with speeds to 2500 rpm, pre-select, 29.5" x 39.5" x 20" box table, 575v/3ph/60hz, s/n: 3233; 3232

- MAS VO50 6' way-type radial arm drill with speeds to 2500 rpm, pre-select, 29.5" x 39.5" x 20" box table, 575v/3ph/60hz, s/n: 2718

- (5) FIRST LC-185VS vertical milling machines with 50" x 10" table, speeds to 4,500 rpm infinitely variable, HEIDENHAIN 2-axis DRO, 575v/3ph/60hz, s/n: 60902571; 60902573; 80203409; 80203408; 8503143

- TOS FGS32 heavy-duty universal milling machine with 15.75" x 55" table, speeds to 1,800 rpm, #50 spindle taper, push button pendant control, 575v/3ph/60hz, s/n: 581

- FORWARD S-243 gear head drill with 19" x 15" t-slot table, speeds to 950 rpm, 575v/3ph/60hz, s/n: 8303019

- FORWARD S-243 gear head drill with 26" x 20" drilled and tapped table, speeds to 950 rpm, 575v/3ph/60hz, s/n: 8401008

- PROTH PSGC50100AHR-B hydraulic surface grinder with 20" x 40" electro magnetic chuck, 14" wheel, coolant, filtration, incremental down feed, wheel dresser, 575v/3ph/60hz, s/n: 31211-02

- PROTH PSGS3060AH hydraulic surface grinder with 12" x 24" electro magnetic chuck, 14" wheel, coolant, incremental down feed, wheel dresser, 575v/3ph/60hz, s/n: 50607-03

- PROTH PSGS3060AH hydraulic surface grinder with 12" x 24" electro magnetic chuck, 14" wheel, coolant, incremental down feed, wheel dresser, 575v/3ph/60hz, s/n: 70297-06

- CHEVALIER FSG-618M conventional surface grinders with 6" x 18" magnetic chucks, 8" wheels, incremental down feed, 575v/3ph/60hz, s/n: A3-71008; 6CXX6

- KENT KGS-200 conventional surface grinder with 6" x 12" magnetic chuck, 8" wheel, incremental down feed, 575v/3ph/60hz, s/n: 860651-4

- KENT KGS-200 conventional surface grinder with 6" x 12" magnetic chuck, 8" wheel, incremental down feed, 575v/3ph/60hz, s/n: N/A

- KENT KGS-200 conventional surface grinder with 6" x 12" magnetic chuck, 8" wheel, incremental down feed, 575v/3ph/60hz, s/n: R950610-U8

- KENT KGS-200 conventional surface grinder with 6"x12" magnetic chuck, 8" wheel, incremental down feed, 575v/3ph/60hz, s/n: 880651-4

- PREGRAPH #2 bench type tool and cutter grinder with collets, s/n: 760127

- SUNNEN MBB-1600 floor-type horizontal precision honing machine, s/n: 10455

- EMPIRE floor-type shot blast cabinet with media recovery and dust collector, s/n: N/A

OVERHEAD BRIDGE CRANES

- (2) P&H 20TON capacity double girder top-running overhead bridge cranes with approx. 33' span, 28' height under hook, s/n: CH18628B; CH19214B

- (4) SOS 10 TON capacity single girder top-running overhead bridge cranes with approx. 40' span, 13.5' height under hook, 2-speed all directions, collision detection, s/n: 961255; 961256; 00-0049; 99 1353

- (3) SOS 5 TON capacity single girder top-running overhead bridge cranes with approx. 40' span, 14' height under hook, 2-speed all directions, collision detection, s/n: 961254; 961253; 961252

- DEMAG 1TON capacity monorail chain hoist, s/n: N/A

- BUDGIT 2TON capacity monorail chain hoist, s/n: N/A

- MFG UNKNOWN approx. 170' crane runway, I-beams, top rail, and buss bar, s/n: n/a

- MFG UNKNOWN approx. 170' crane runway, I-beams, top rail, and buss bar, s/n: n/a

- MFG UNKNOWN approx. 100' of buss bar, top rail and I beam

ROLLING STOCK

- CATERPILLAR T300 30,000 lbs capacity LPG forklift with 106" maximum vertical reach, 2-stage mast, 3944 HRS (recorded on meter at time of listing), s/n: 71L00791P

- TOYOTA 8FGCU30 5,000 lbs capacity LPG forklift with 198" maximum vertical reach, 3-stage mast, side-shift, cushion tires, 8332 HRS (recorded on meter at time of listing), s/n: 13134

- SKYJACK SJIII 3220 electric scissor lift with 20' maximum vertical lift, built-in onboard charger, 500LB maximum platform capacity, s/n: N/A

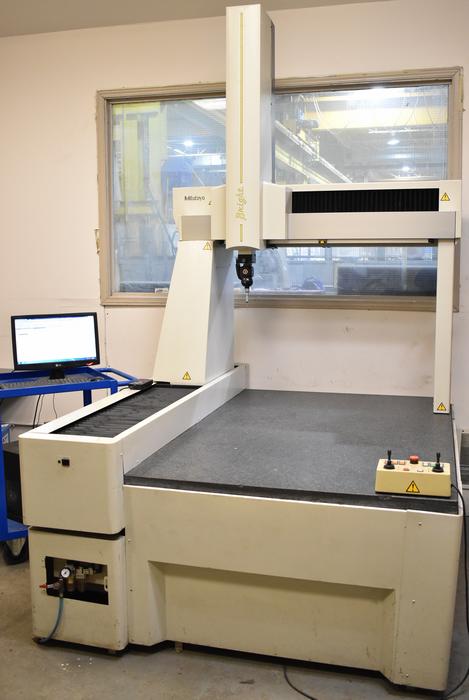

Q.C. & INSPECTION

- BROWN AND SHARPE DEA SCIROCCO 15-10-09 coordinate measuring machine with RENISHAW PH9 touch probe, HEXAGON METROLOGY INSPECT VERSION 2.5 software, 59.05” x 39.37” x 33.85” measuring envelope, s/n: 5065

- MITUTOYO BRIGHT BRT 910 coordinate measuring machine with 46" x 68" drilled and tapped granite plate, RENISHAW PH9A touch probe, TRIDENT PURE STREAM dryer, WINDOWS PC based control and MITUTOYO GEOPACK software, s/n: 0033603

- MITUTOYO PH-350 optical comparator with 13" diameter screen, s/n: 60037

- ROCKWELL HR-150A conventional hardness tester, s/n: 1146

FACTORY SUPPORT EQUIPMENT

- FLEXARM magnetic-based pneumatic tapping arm, s/n: N/A

- SPERONI STP MAJIS400 optical tool pre-setter, s/n: 000531D

- ATLAS COPCO (2014) GA22VSD+FF 30HP variable speed air compressor, 575v/3ph/60hz, s/n: API823127

- ATLAS COPCO (1999) GA37FF 50HP air compressor, 575v/3ph/60hz, s/n: AII 363731

- PNEUMATECH refrigerated air dryer, 575v/3ph/60hz, s/n: N/A

- HP DESIGNJET T770 large format plotter/printer, s/n: CN9B92H01Q

- DIMENSION BST PROTYPING 3D printer, s/n: N/A

ALSO:

- FAST MILL PRECISION CLAMPING SYSTEM with tables, pucks, rods and clamping; LARGE SELECTION of MACHINE TOOL ACCESSORIES including angle plates, box tables, rotary indexing tables, (3) punch formers, radius dressers, machine vises, MAGNETIC PLUS multi-zone electromagnetic chuck with controller, magnetic chucks and magnetic sine plates; LARGE ASSORTMENT of CAT50, CAT 40, HSK-A63 and #50 taper tool holders; HUGE QTY of PERISHABLE TOOLING comprising drills, reamers, end mills, taps, carbide cutters, carbide insert cutters, carbide inserts and holders; SELECTION OF INSPECTION and Q.C. equipment including (3) 18"x24"x3" granite surface plates with stands, 30"x60"x9" granite surface plate with stand, angle plates, (6) MITUTOYO digital height gauges; FACTORY EQUIPMENT including but not limited to lifting magnets, (6) dumping hoppers, grinding wheels, shop carts, shop tables, toolboxes, shop fans, rigging and lifting supplies, (3) pedestal grinders, large quantity of engineered sawhorses, eye bolts, pigeonhole cabinets, cabinets with perishable tooling, power and hand tools, welding table with clamps/supplies, strapping caddy with packaging supplies, (2) GREENLEE job boxes, DRAKE arbor press, digital crane scale, spare uncoiler, (3) spare transformers, SUBARU 4.5EX13 gas powered water pump, heavy-duty die racks, (4) LISTA cabinets with tools, bench-type chamfer and deburring machine; office furniture, computers, business machines & MUCH MORE!