Surplus Assets of

Garry Machine Manufacturing Inc. – Plant 2

Large Capacity CNC Turning & Machining Facility

Date

Tuesday, July 10, 2018

Start Time

10:30 AM EDT

Inspection

Monday, July 9 from 9:00 A.M. to 5:00 P.M. and morning of auction to start of auction.

Removal

Small items: Wednesday, July 11 by 5:00 P.M.

Remaining items: Tuesday, July 24 by 5:00 P.M.

Industry

FEATURING: POREBA (2006) TRP 93 X 6M, 36”/48” x 240” large capacity gap bed engine lathe; LEADWELL (2007) LTC50 BXXL, large capacity CNC turning center; LEADWELL LTC50 CXL, large capacity CNC turning center; DAEWOO (1998) PUMA 400L, CNC turning center; HITACHI SEIKI (2001) HS 500, CNC twin pallet horizontal machining center; TOS W100A, 4” table type horizontal boring mill; TOS SUS 63H, 26” x 260” engine lathe; PBR TM30, 24” x 216” engine lathe; (5) POTISJE engine lathes up to 170” centers; EVERISING (2007) H-360HA, horizontal saw; CHEVALIER 10” x 20” hydraulic surface grinder; BANDAG (REBUILT IN 2006) autoclave SOLD!; (7) TOYOTA, DAEWOO & TCM forklifts up to 4900 LB capacity; MITUTOYO PH14LS, optical comparator w/ QUADRA-CHECK 200 control; DEVAIR (2006) 15HP air compressor package & dryer; GMC 7500, truck w/ roll-up tarp system; (10+) Cantilever material racks; ASSORTMENT OF 40 & 50 taper tool holders, tool carts, jib cranes, raw material, metal stacking bins & MORE!

CNC TURNING CENTERS

- LEADWELL (2007) LTC-50BXXL CNC turning center with FANUC SERIES Oi-TC CNC control, 15” 3 jaw chuck, 32” swing over bed, 31” max. turning diameter, 158” max. turning length, 4.5” spindle bore, 12 station turret, speeds to 1500 RPM, 50 HP spindle motor, coolant, chip conveyor, (2) SMW-AUTOBLOCK hydraulic steady rests, hydraulic tailstock, tool checker arm, s/n: L2TJF1247

- LEADWELL LTC-50CXL CNC turning center with FANUC SERIES O-T CNC control, 18” 3 jaw chuck, 32” swing over bed, 31” max. turning diameter, 120” max. turning length, approx. 4” spindle bore, 12 station turret, speeds to 1500 RPM, 60 HP spindle motor, coolant, chip conveyor, SMW-AUTOBLOCK hydraulic steady rest, hydraulic tailstock, s/n: L29303014

- DAEWOO PUMA 400L CNC turning center with FANUC SERIES 18-T CNC control, 15” 3 jaw chuck, 26” swing over bed, 21” max. turning diameter, 85” max. turning length, approx. 4” spindle bore, 10 station turret, speeds to 3000 RPM, 50 HP spindle motor, coolant, chip conveyor, SMW-AUTOBLOCK hydraulic steady rest, hydraulic tailstock, tool checker arm, s/n: P35L0158

- HITACHI-SEIKI HT-25S CNC turning center with FANUC 10TE-F CNC control, 10” 3 jaw chuck, 20” swing over bed, 10” max. turning diameter, 23” max. turning length, 2.5” spindle bore, 10 station turret, speeds to 3600 RPM, 15 HP spindle motor, chip conveyor, hydraulic tailstock, tool checker arm, s/n: 25197SC

RUBBER WORKING MACHINES

REMCO (2006) TSB 250TX270 THERMOSET strip builder with 50” max. diameter capacity, 270” max. length capacity, spindle speeds to 90 RPM, 3” cold feed extruder, integrated pneumatic tape wrap attachment, motorized tailstock, hot knife heater, s/n: 1796-460-90-F06SOLD!REMCO (2006) GGSY 232X270 computerized grinder-groover with touch screen PLC control, 32” max. diameter capacity, 270” max. length capacity, spindle speeds to 7200 RPM, 12” wheel dresser, automatic lube, diagnostic software, s/n: 1797-460-F06SOLD!

FABRICATION EQUIPMENT

- TOS W100A table type horizontal boring mill with 4” spindle, 49”x49” power rotary table, 44” vertical travel, 62” cross travel, #50 taper, speeds to 1120 RPM, facing head, MITUTOYO 3 axis DRO, vertical milling head, spindle support, s/n: 20-42

- CHEVALIER FSG-3A1020 hydraulic surface grinder with 26”x10” magnetic chuck, coolant, incremental downfeed, s/n: N3795002

- CHUNG-WEI G8635 hydraulic surface grinder with 24”x12” magnetic chuck, coolant, s/n: 86627

BANDAG (2006 REBUILT BY PATTERSON) autoclave with PATTERSON PLC touchscreen control, 100 PSIG max. work pressure, 300 deg. F. max. temperature, 7.5 HP motor, 25’x58” dia. enclosure, s/n: 06CA1771SOLD!- W.A. WHITNEY 815-171 hydraulic punch press with 100 ton capacity, 24” throat, 45”x42” table, 30 HP hydraulic power pack, s/n: 815-171-25417

- CINCINNATI BICKFORD H-10 4’ radial arm drill with 48” column, speeds to 2000 RPM, 24”x18”x20” box table, s/n: 2110

- DOALL (2006) 2013-V vertical band saw with 20” throat, 26”x26” table, 18” max. work height, s/n: 571-06402

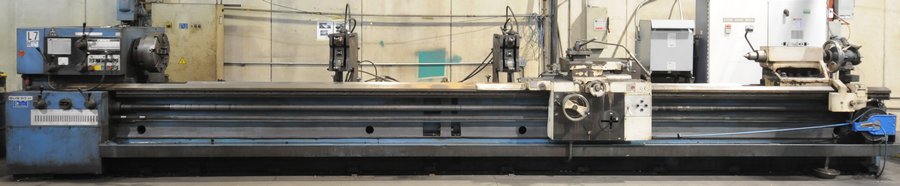

LATHES

- POREBA TRP 93/6M gap bed engine lathe with 32” swing, 248” between centers, 4” spindle bore, speeds to 800 RPM, inch/metric threading, chuck, s/n: 7402-06-1104-05

- TOS SUS 63 H engine lathe with 26” swing, 260” between centers, 3” spindle bore, speeds to 1120 RPM, inch/metric threading, chuck, hydraulic steadies, steadies, s/n: 04-55-159

- POSTISJE 24x170 gap bed engine lathe with 24” swing, 170” between centers, 3.5” spindle bore, speeds to 2000 RPM, inch/metric threading, chuck, s/n: 2685826

- (2) POSTISJE 24x125 gap bed engine lathe with 24” swing, 125” between centers, 3.5” spindle bore, speeds to 1100 RPM, inch/metric threading, chucks, steadies, s/n: 045658748, 045658743

- MEEHANITE SU582 gap bed engine lathe with 24” swing, 122” between centers, 3” spindle bore, speeds to 2000 RPM, inch/metric threading, chuck, steadies, coolant, s/n: n/a

WELDERS

- LINCOLN ELECTRIC PRECISION TIG 375 digital aluminum TIG welder, s/n: U1060307911

- HOBART STELLAR AT DC-CC/CV digital aluminum DC inverter arc welder with HOBART OLYMPIC XR-A extended reach wire feeder, cables & gun, s/n: KK147971

- NELSON TRW SERIES 5000 MODEL 101 digital stud welder with cables & gun, s/n: SMA-9809

MATERIAL HANDLING

- (2) DAEWOO GC30E LPG forklifts with 4800 lb. capacity, 186” vertical lift, side shift, indoor tires, s/n: GC30E-3FQ-00377, GC30E-3FQ-00376

- CLARK CGC25 LPG forklift with 2500 lb. capacity, 240” vertical lift, side shift, indoor tires, s/n: C365L-1068-9404

- CLARK C500-90LP LPG forklift with 8300 lb. capacity, 114” vertical lift, side shift, indoor tires, s/n: 685-36-1596

- (4) MFG. UNKNOWN wall mounted jib arms with ½ ton capacity, CM ½ ton capacity electric hoist

FACTORY SUPPORT EQUIPMENT

- DEVAIR SC30 rotary screw air compressor with 30 HP, s/n: 63055

- DEVAIR (2006) PRO DRY ASD 150AL refrigerated air dryer, s/n: 06M-005037

- DEVAIR (2006) air receiver tank with 120 gal. capacity

- GUYSON shot blast system consisting of GUYSON MODEL 10 blast cleaning cabinet with 60”x60”x60” cabinet, variable speed rotary table; GUYSON 150/16 cyclonic dust collector; GUYSON D-1000 cartridge type dust collector; s/n: M46206, C46206, D46206

- PLYMOVENT (2012) MFC-1200 portable snorkel-type fume extractor, s/n: 9156377

- (2) PLYMOVENT EMK-1402 portable snorkel-type fume extractors

ALSO:

MITUTOYO PH14LS optical comparator, (2) SMOG HOGG mist collectors; (10+) cantilever racks; WIDE SELECTION of TOOLING including end mills, drills, boring bars, reamers; #40 & #50 tool holders; power tools; hand tools; (50+) wire mesh bins; inspection equipment; machine tooling and MUCH MORE!