Immaculate CNC Facility

Ultra-Modern & Multi-Axis CNC Machining Facility

Date

Tuesday, December 10, 2019

Start Time

10:30 AM EST

Inspection

Monday, December 9 from 9:00 A.M. to 5:00 P.M. and morning of auction to start of auction.

Removal

Small items: Wednesday, December 11 by 5:00 P.M.

Remaining items: Friday, December 27 by 5:00 P.M.

Location

Assets Located in ON, Canada

Industry

Corporate Assets Inc., is pleased to bring to market one of the nicest CNC machine tool auctions in years! This facility ran custom & prototype jobs, with exceptionally low hour usage on all machinery.

A brief summary of assets are as follows: DMG MORI (2015 & INSTALLED BRAND NEW IN 2017) DMU-65, 5-Axis CNC vertical machining center; MATSUURA (2014) MX-520, 5-Axis CNC vertical machining center; HURCO (2012) VMX-42Ui, 5-Axis CNC vertical machining center; HURCO (2013) VMX-50i, CNC vertical machining center; (2) HURCO (2015) VM-10i, CNC vertical machining centers; (2) DMG MORI (2016 & 2015) ECOTURN 450, CNC turning centers; (2) UNIVERSAL (BRAND NEW NEVER USED & 2018) UR10e, multi-axis collaborative robots (50K USD NEW EACH); ZEISS (2007) CONTURA GT 10-12-6, CNC bridge type CMM; CHEVALIER (2016) CNC high precision surface grinder; HWACHEON (2001) TTC-8, CNC dual spindle horizontal turning center; HWACHEON ECO-2SP3, CNC dual spindle horizontal turning center; OKUMA & HOWA 2SP-V40, CNC dual spindle vertical turning center; DARBERT vertical milling machine w/ power feed; KING roll in vertical saw; LARGE OFFERING OF high precision tooling, machine tool accessories, 5-Axis machining fixtures, HSK63 tool holder, CAT 40 & 50 tool holders, perishable tooling, carbide high speed tooling, inspection equipment & accessories, 10 transformers, sea container, general factory support equipment & MORE!

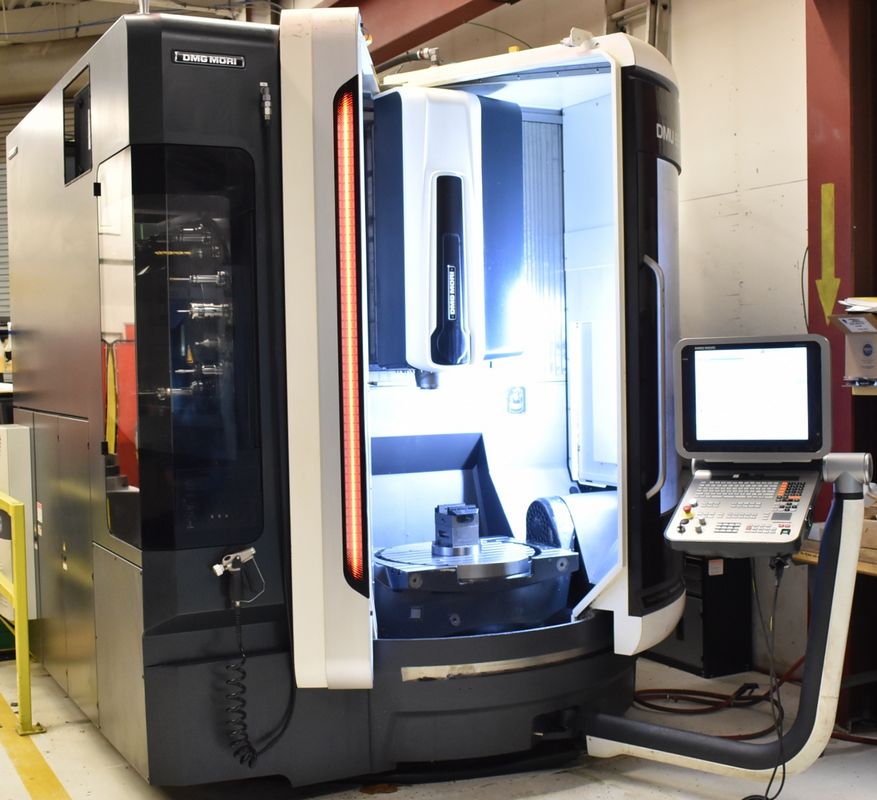

5 AXIS CNC VERTICAL MACHINING CENTERS

- DMG MORI (2015) (INSTALLED NEW IN 2017) DMU 65 MONOBLOCK, 5 axis CNC vertical machining center with 3D HEIDENHAIN TNC640 control, 25.6” diameter rotary table, travels: X–28.9”, Y–25.6”, Z–22”, A—120 deg./+120 deg., C–360 deg., speeds to 18,000 RPM, HSK63 taper, 60 station ATC, 46 HP, BLUM laser tool measuring, RENISHAW infrared measuring probe, 3D quick set, automation package included (two port thru the table hydraulic lines, robot ready with auto side door, PROFIBUS interface – $27,000 option), high pressure coolant thru spindle, rotating clear window view, chip conveyor, 2344 cutting hrs (recorded at time of listing), s/n: 12140013283

- MATSUURA (2014) (INSTALLED NEW IN 2015) MX-520 5 axis CNC vertical machining center with MATSUURA G-TECH 31I CNC control, 19.7” diameter rotary table, travels: X – 24.8”, Y – 22.05”, Z – 20.08”, A -125deg./+30 deg., C –360 deg., speeds to 12,000 RPM, work offset touch probe, CAT 40 taper, 60 station ATC, 300 PSI coolant thru spindle, chip conveyor, 2126 cutting hrs (recorded at time of listing), s/n: 19595

- HURCO (2012) VMX42UI 5 axis CNC vertical machining center with HURCO dual screen CNC control, 13.7” diameter rotary table, travels – X–42”, Y–24”, Z–24”, A—110 deg./+30 deg. at .001deg.increments., C–360,000 deg. (.001 deg. increments), RENISHAW part and tool probe, 300 PSI coolant thru spindle, speeds to 10,000 RPM, CAT 40 taper, 40 station ATC, 24 HP, chip conveyor, 2992hrs (recorded at time of listing), s/n: M444U-16003122CLCS

CNC VERTICAL MACHINING CENTERS

- HURCO (2013) VMX50I /50 CNC vertical machining center with HURCO dual screen CNC control, 59”x26” table, travels: X–50”, Y–26”, Z–24”, speeds to 6500 RPM, CAT 50 taper, 30 station ATC, 25 HP, high pressure coolant thru spindle, chip conveyor, 2532 hrs (recorded at time of listing), s/n: M553-1600363EEMCS

- HURCO (2015) VM10I CNC vertical machining center with HURCO MAX CNC control, 30”x16” table, travels: X–26”, Y–16”, Z–20”, speeds to 10,000 RPM, DXF transfer, CAT 40 taper, 20 station ATC, 15 HP, 300 PSI coolant thru spindle, chip conveyor, 2649 hrs (recorded at time of listing), s/n: S10-1601715DAAAH

- HURCO (2015) VM10I CNC vertical machining center with HURCO MAX CNC control, 30”x16” table, travels: X–26”, Y–16”, Z–20”, speeds to 10,000 RPM, DXF transfer, CAT 40 taper, 20 station ATC, 15 HP, coolant, chip conveyor, 2483 hrs (recorded at time of listing), s/n: S10-1602715DAAAH

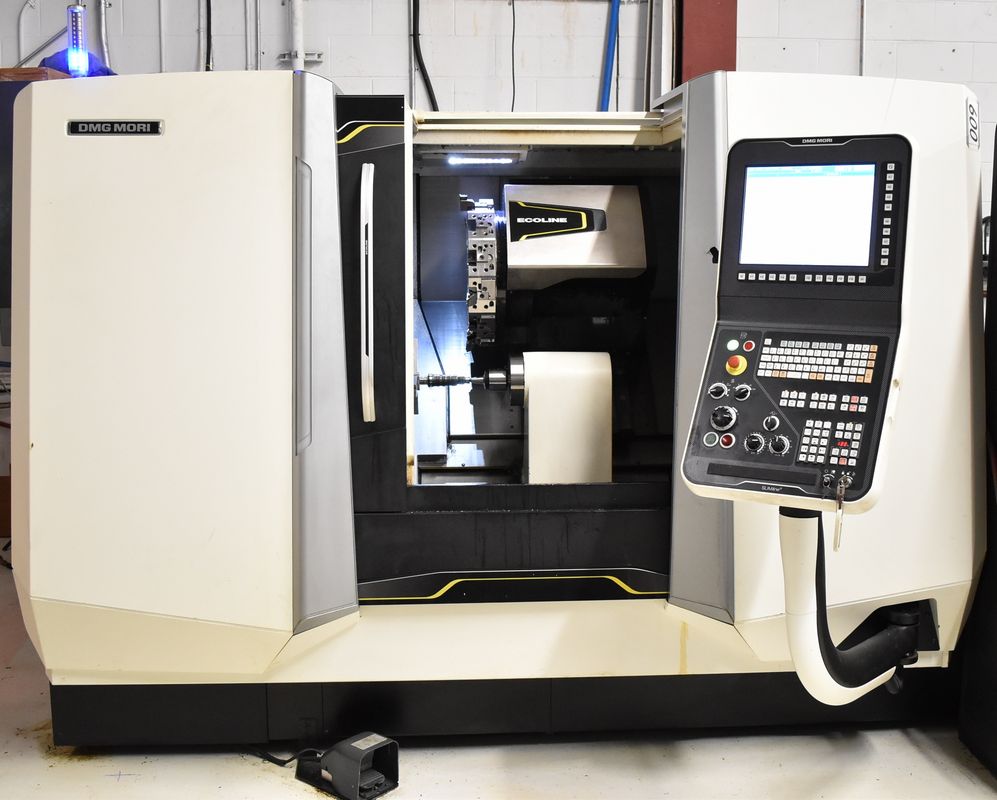

CNC TURNING CENTERS

- DMG MORI (2015) ECOTURN 450 CNC turning center with DMG MORI SLIMLINE CNC M730BM control, 10” chuck, 26.77” swing over bed, 26.97” distance between centers, 15.98” max. turning diameter, 23.6” max. turning length, 3.58” spindle bore, programmable tail-stock, 12 station turret, speeds to 4000 RPM, 24 HP spindle motor, conversational programming with simulation, tool pre-setter probe arm, chip conveyor, 1138 spindle hrs (recorded at time of listing), s/n: ET450150335

- DMG MORI (2015) ECOTURN 450 CNC turning center with DMG MORI SLIMLINE CNC M730BM control, 10” chuck, 26.77” swing over bed, 26.97” distance between centers, 15.98” max. turning diameter, 23.6” max. turning length, 3.58” spindle bore, programmable tail-stock, 12 station turret, speeds to 4000 RPM, 24 HP spindle motor, conversational programming with simulation, tool pre-setter probe arm, chip conveyor, 1339 spindle hrs (recorded at time of listing), s/n: ET450140913

4 AXIS CNC TWIN SPINDLE TURNING CENTERS

- HWACHEON (2001) TTC-8 4 axis CNC twin spindle twin turret turning center with FANUC SERIES 18-T CNC control, (2) 8” chucks, 14.8” distance between centers, 12” max. turning diameter, 8.2” max. turning length, spindle hole size 2.8”, (2) 10 station turrets, speeds to 5000 RPM, 20 HP spindle motor, s/n: M078349F5CA

- HWACHEON ECO-2SP3 4 axis CNC twin spindle twin turret turning center with FANUC SERIES O-T CNC control, (2) 10” chucks, 16” distance between spindles, 12.2” max. machining diameter, 8.2” max. machining length, (2) 8 station turrets, speeds to 2000 RPM, approx. 14 HP spindle motor, s/n: M0763420-05

- OKUMA & HOWA (2004) 2SP-V40 4 axis CNC twin spindle vertical lathe with FANUC SERIES 18I-TB CNC control, 19.6” max. swing, 15.75” max. cutting diameter, 17.72” max. cutting length, (2) 12 station turrets, speeds to 2500 RPM, 25 HP, coolant, twin chip conveyors, s/n: 4023

CNC HYDRAULIC SURFACE GRINDER

- CHEVALIER (2017) FSG-1224ADIII CNC hydraulic surface grinder with CHEVALIER 3 axis CNC 8” touch screen control, 24”x 12” electromagnetic chuck, machine lamp, 24” max. grinding length, 12” max. grinding width, max. distance from table surface to spindle centerline 24.75”, coolant system with auto paper feed, incremental down feed, coolant, s/n: FFB168002

CONVENTIONAL MACHINERY

- DARBERT MICROCUT vertical milling machine with 49”x9” table, speeds to 4200 RPM, HEIDENHAIN 2 axis DRO, power table, s/n: 9909-21

- KING INDUSTRIAL (2012) KC-914H metal cutting vertical band saw with 19”x30” table, 10” throat, 15” max. work piece height, s/n: 24A0014

- KING INDUSTRIAL 10X22 benchtop metal lathe with 10” swing over bed, 22” between centers, speeds to 2400 RPM, 1” spindle bore, s/n: n/a

SUPPORT EQUIPMENT

- ATLAS COPCO (2013) GX11FF tank mounted rotary screw air compressor with 11 HP, 16,129 hrs(recorded at time of listing), s/n: CAI679403

- HINES (RECONDITIONED 2017- used for 2 months only) HVR-20TB single plane vertical balancing machine with 16” max. rotor dia., ½ HP, drill press, laptop with dynamic balancing software, s/n: 3096-41

- (2) UNIVERSAL ROBOTS (2018) UR10E collaborative industrial robotic arm with UNIVERSAL ROBOTS touch screen control, max. capacity 10 kg, s/n: 20185000569, n/a (1 NEW IN BOX)

- ROBOTIQ (2018) AGC-ES-UR-KIT-85 adaptive gripper (NEVER USED)

INSPECTION EQUIPMENT

- ZEISS (2007) CONTURA G2 10.12.6 bridge type CMM with 25”x61” granite table, measuring range approx.: X 40”, Y – 47”, Z – 24”, 4 station tool changer rack, ZEISS probe kit with various probes and tooling (worth over $15,000 some still new in boxes), ZEISS joystick operator control, PC monitor and printer, s/n: 200708500957

- MITUTOYO (2016) LSM-6200 & LSM-506S laser scan micrometers with 1 - 60mm measurement (NEVER USED)

ALSO:

CHUCKS and associated clamping; BUTCHER BLOCK top work benches; hand tools; perishable tooling and MORE!