Joseph Robertson Foundries Limited

Late Model Non-Ferrous Casting & Machining Operation

Date

Thursday, August 10, 2023

Start Time

10:30 AM EDT

Inspection

Wednesday, August 9 from 9 AM to 4 PM or by appointment. Please email [email protected] to arrange.

Removal

All assets must be removed no later than Thursday, August 31 by appointment only. Rigging details below.

FEATURING: SCHAEFER (2011) 1,000 lb. cap. natural gas-fired crucible melting furnace; LINDBERG/MPH 61-C600-CRU 600 lb. cap. natural gas-fired crucible melting furnace; INDUCTOTHERM POWER-TRAK SERIES R 300 lb. cap. medium frequency lift swing electric induction melting furnace; RAYTEQ DC-425 775 lb. cap. electric resistance melting furnace; HUNTER HMP/HMH automatic molding line in 14"x19" flask configuration with HUNTER (2004) HMP-10G automatic molding machine & HUNTER HMH-210 12x2 mold carrousel; OSBORN 3161-12 ROTA-LIFT jolt squeeze molding machine; (2) STAHL AUTOCAST 18x24-30 hydraulic mold machines; SIMPSON MODEL #1-1/2F 28.75”x64” dia. cap. dual station mix-muller; COOPER-CHAPMAN CAG-2428-88 hot box shell core machine; COOPER-CHAPMAN CAG-2021-70 hot box shell core machine; ANYANG FORGING PRESS (2007) Y83-160 160 ton cap. metal scrap hydraulic briquetting machine; WHEELABRATOR TUMBLAST tumbler cleaning machine; BROTHER (2019) R650X1 high torque CNC twin-pallet vertical machining center; MATSUURA (2018) R.PLUS-800 CNC twin-pallet vertical machining center; MORI-SEIKI CV-500A CNC twin-pallet vertical machining center; MORI-SEIKI (2007) DURAVERTICAL 5100 CNC vertical machining center; MORI-SEIKI (2005) NL2500MC/700 CNC live milling & turning center; MORI-SEIKI SL-25 CNC turning center; HYSTER S50XM 5,000 lb. cap. LPG forklift; COMPAIR HYDROVANE 218PUAS 50 HP rotary screw air compressor; INGERSOLL-RAND RS18I-A145 25 HP rotary screw air compressor; LINCOLN ELECTRIC PRECISION TIG 375 digital TIG welder; DOALL 36-W vertical band saw; MITUTOYO BRIGHT APEX A504 CMM; (2) 40’ storage containers; LARGE OFFERING of CAT 40 & BT30 tool holders and MORE!

Rigging and Removal Details

THE EXCLUSIVE RIGGER FOR THIS SALE IS:

Titan Machinery Movers

Jordan Whicher

C: 905 875 9768

[email protected]

*All assets must be removed no later than Thursday, August 31. For everyone’s safety removal at this site is conducted strictly by appointment only. All machinery buyers must contact Jordan Whicher at 905 875 9768 to set their pick-up appointments upon payment in full.

*Further information on removal details can be found in the Terms & Conditions tab or in the Lot Catalogue.

TRUCKING AND TRANSPORT SERVICES:

Trucking and transport services, including cross-border logistics, are available through Fuze Logistics Inc. Please contact Chris Tan for a firm quote or any questions regarding transportation.

Fuze Logistics Services Inc.

Chris Tan

514.799.4162

[email protected]

FOUNDRY EQUIPMENT

- SCHAEFER (2011) natural gas-fired crucible melting furnace with 1,000 lb. capacity, 300-350 lb/hr melt rate, 1,250,000 BTU/hr, min. purge time 1 min, (2) digital temperature controls, s/n: 07-1210-0105

- LINDBERG/MPH 61-C600-CRU natural gas-fired crucible melting furnace with 600 lb. capacity, 900,000 BTU input, 1,500 deg. F max. temperature, 1/3 HP, (2) digital temperature controllers, s/n: C-8039

- INDUCTOTHERM POWER-TRAK SERIES R medium frequency lift swing electric induction melting furnace with 330 lb. capacity, 200 KVA power supply with 175 kW output, INDUCTOTHERM VIP furnace control, 52” reach jib arm with 92” under arm, water cooling system with rooftop chiller unit, s/n: 04J-183072-246-11

- RAYTEQ DC-425 electric resistance melting furnace with 775 lb. capacity, 425 lb/hr melt rate, RAYTEQ control with digital temperature controllers, s/n:492

- LINDBERG HEVI-DUTY 11EC-30483012E electric production box cyclone furnace with elevator, 1250 deg. F max. temperature, 60 kW, HONEYWELL chart recorder, s/n: EL69836

- HUNTER HMP/HMH (2011 OEM FACTORY RECONDITIONED) automatic molding line in 14"x19" flask configuration with 14"x19" capability, consisting of: HUNTER (2004) HMP-10G automatic molding machine with 14”x19” capacity, 79” working clearance, ATS PANELMATE EPRO PS touch screen control, s/n: 2004MPG1234; WARD 290”x16” roller transfer conveyor; HUNTER HMH-210 12x2 mold carrousel with transfer robot, weights and jackets, s/n: 74M161; shuttle conveyor and transfer table; inclined transfer belt conveyor; WARD 114 HIGH hydraulic lift dumper, s/n: 116MD2KM; WARD 1000HF 532”x30” oscillating vibratory conveyor, s/n: 202VC30X44; screen shaker (components may be offered separately)

- OSBORN 3161-12 ROTA-LIFT jolt squeeze molding machine with 12” squeeze stroke, 16” squeeze cylinder diameter, 20”-30” flask length, s/n: 15824-F

- BEST WESTERN V-2375 QCK jolt squeeze molding machine, s/n: DH-6828

- STAHL AUTOCAST 18x24-20 hydraulic mold machine with 12,000 lb. clamping pressure, 4” bore, 20” stroke, 36”x27” max. mold size, STAHL SUPER DUAL power/control unit, s/n: 0242

- STAHL AUTOCAST 18x24-20 hydraulic mold machine with 12,000 lb. clamping pressure, 4” bore, 20” stroke, 36”x27” max. mold size, 15 HP hydraulic power pack, CPI AUTOMATION controls with MITSUBISHI AB50GOT control, s/n: 0248

- STAHL AUTOCAST 30x30-30 self-pouring permanent mold machine with 5” bore, 30” stroke, 34”x34” max. mold size, s/n: n/a

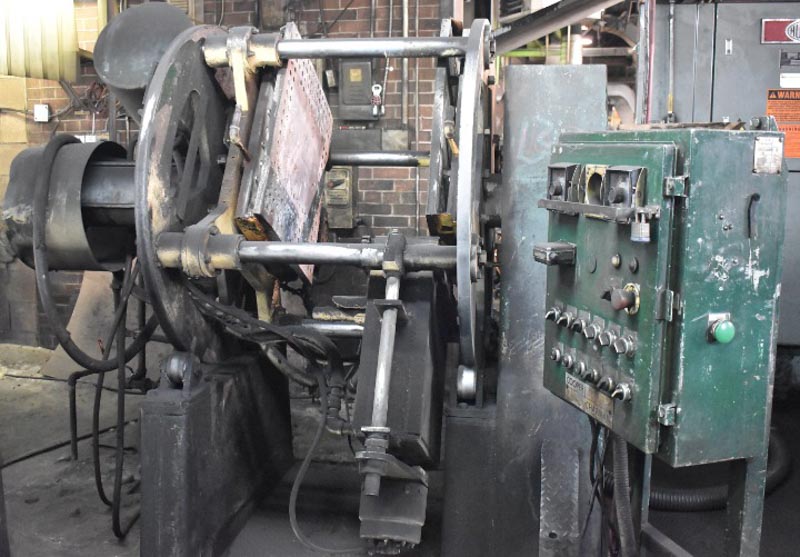

- COOPER-CHAPMAN CAG-2428-88 hot box shell core machine with 24”x28” platens, s/n: 182

- COOPER-CHAPMAN CAG-2021-70 hot box shell core machine with 20”x22” platens, s/n: 216

AUTOMATED SAND HANDLING SYSTEM

- JRF-SIMPSON fully automatic sand handling system with SIEMENS SIMATIC PANEL TOUCH touchscreen PLC control consisting of: SIMPSON MODEL #1-1/2F dual station mix-muller with 28.75”x64” dia. capacity, 15 HP, 1800 RPM, 18” discharge opening, s/n: E-7207001; (2) sand transfer conveyors; (2) bucket elevator conveyors; holding silos with pneumatic/manual discharge hoppers; sand distribution system; vibratory shaker table; vibratory mold breaker table; sifter scree; controls and integration; s/n n/a (components may be offered separately)

FINISHING DEPARTMENT

- WHEELABRATOR TUMBLAST tumbler type shot blast cleaning machine with dumper elevator, 36”x42” MANGALLOY belt and sides, (1) 15 HP wheel, (8) blades, s/n: A119720

- WHEELABRATOR TUMBLAST tumbler type shot blast cleaning machine with 27”x36” rubber belt and MANGALLOY sides, (1) 15 HP wheel, (8) blades, s/n:, 2,257 hours (recorded on meter at time of listing), elevator, s/n: n/a

HIGH SPEED CNC TWIN-PALLET VERTICAL MACHINING CENTERS

- BROTHER (2019) R650X1 high speed, high torque CNC twin-pallet vertical machining center with BROTHER CNC control, (2) 31.5”x18.75” drilled & tapped pallets, travels: X – 25.6”; Y – 15.7”; Z – 12”, 21.9” max. distance spindle nose to table top, 16,000 RPM max. spindle speed, BT30 spindle taper, 22 station ATC, coolant-through spindle, BIG PLUS simultaneous contact spindle, coolant, chip conveyor, s/n: 112109

- MATSUURA (2018) R.PLUS-800 high speed CNC twin-pallet vertical machining center with MATSUURA G-TECH 30i CNC control, (2) 34”x21” drilled & tapped pallets, travels: X – 31.5”; Y – 21.65”; Z – 19.68”, 25.59” max. distance spindle nose to table top, 12,000 RPM max. spindle speed, CAT 40 spindle taper, 40 station ATC, coolant-through spindle, RENISHAW OTS-AA compact 3D touch-trigger tool setter system, coolant, chip conveyor, s/n: 21258

- MORI-SEIKI CV-500A CNC twin-pallet vertical machining center with MORI-SEIKI MSC-803 CNC control, (2) 30”x22” drilled & tapped pallets, travels: X - 20”; Y - 20”; Z - 20”, 27” max. distance spindle nose to table top, 8,000 RPM spindle speed, CAT 40 spindle taper, 25 station ATC, coolant, chip conveyor, s/n: 417

HIGH SPEED CNC VERTICAL MACHINING CENTER

- MORI-SEIKI (2007) DURAVERTICAL 5100 CNC vertical machining center with MORI-SEIKI MSC-504 CNC control, 53”x23.75” table, travels: X – 41.3”; Y – 20.9”; Z – 20.1”, 26” max. distance spindle nose to table top, 10,000 RPM spindle speed, CAT 40 spindle taper, 30 station ATC, 4th axis plug-in, coolant-through spindle, coolant, chip conveyor, s/n: DV005GE0734

CNC LIVE MILLING & TURNING CENTER

- MORI-SEIKI (2005) NL2500MC/700 CNC live milling & turning center with MORI-SEIKI MSX-850 CNC control, 10” 3-jaw chuck, 36.4” swing over bed, 29.7” swing over cross slide, 14.02” max. turning diameter, 27.76” max. turning length, 3” spindle bore, 12-station turret, speeds to 4,000 RPM, tailstock, coolant, chip conveyor, s/n: NL251EK1411

CNC TURNING CENTER

- MORI-SEIKI SL-25 CNC turning center with FANUC 10-T CNC control, 10” 3-jaw chuck, 20.5” swing over bed, 13.8” swing over cross slide, 10.2” max. turning diameter, 24.6” max. turning length, 2.75” spindle bore, 10 station turret, speeds to 3500 RPM, tailstock, chip conveyor, s/n: 1622

CONVENTIONAL MACHINE TOOLS

- DOALL 36-W vertical band saw with 36.5”x30” table, 35.5” throat, 25” max. workpiece height, s/n: 31-591903

- FORD-SMITH 14” double end sanding/polishing machine, s/n: n/a

- FORD-SMITH 12” double end sanding/polishing machine, s/n: n/a

- LINCOLN ELECTRIC PRECISION TIG 375 digital TIG welder with CROSSFIRE SLJ-10 cooler, cables & gun, s/n: n/a

CO-ORDINATE MEASURING MACHINE

- MITUTOYO BRIGHT APEX A504 CMM with 34”x28” granite table, 52”x21.75”x22” measurement envelope, RENISHAW MH201 touch probe, joystick control, PC & printer, s/n: N0404111

LIBS METAL ALLOY ANALYZER

- RIGAKU KT-100S LIBS metal alloy analyzer with touchscreen display, USB & WIFI connectivity, docking station & carrying case, s/n 3023

FACTORY EQUIPMENT

- COMPAIR HYDROVANE 218PUAS 50 HP rotary screw air compressor with 115 PSI, 56,781 hrs, s/n: C23A90306C001578

- INGERSOLL-RAND RS18I-A145 25 HP rotary screw air compressor with 90 PSIG, 99 CFM, 3668 RPM, 7,983 hrs (recorded on meter at time of listing), s/n: CBV676024

- DUROVAC (2017) DVP25-6M-BDTM industrial vacuum unit with GARDNER DENVER SUTORBILT 2350 RPM positive displacement blower, 25 HP electric motor, s/n: 8395

- ANYANG FORGING PRESS (2007) Y83-160 metal scrap hydraulic briquetting machine with 160 ton capacity, 2.36”x3.14” max. block size, 17.71” stroke, conveyor, s/n: 7012

ROLLING STOCK

- HYSTER S50XM 5,000 lb. capacity LPG forklift with 189” max. lift height, 3-stage mast, side shift, solid tires, 9,147 hrs (recorded on meter at time of listing), s/n: D187V11931V

- TOYOTA 7HBW23 4500 lb. capacity 24V electric walk-behind pallet truck with on-board charger, s/n: 7HBW23-44814

ALSO:

- (2) 40’ storage containers; LARGE OFFERING of CAT 40 & BT30 tool holders; sand casting frames; PERISHABLE TOOLING including drills, end mills, taps; INSPECTION EQUIPMENT including height gauges, pin gauge sets, dial gauges, outside micrometers, go no-go gauges; hand tools; electric tools; welding accessories; shop tables, racking and MORE!