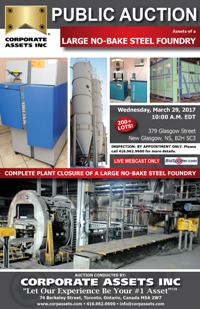

Assets of a

Large No-Bake Steel Foundry

Upcoming Foundry Event

Date

Wednesday, March 29, 2017

Start Time

11:00 AM ADT

Inspection

BY APPOINTMENT ONLY. Please call 416.962.9600 for more details.

Removal

BY APPOINTMENT ONLY. Please call 416.962.9600 for more details.

Industry

THIS SALE WILL BE CONDUCTED AS A LIVE ONLINE WEBCAST.

Complete Plant Closure of a Large No-Bake Steel Foundry Featuring: KLOSTER (2002) 9 line slick loop no-bake molding system; Complete sand casting handling system with many parts REBUILT IN 2009; GUDGEON (2007) TF3000 THERMFIRE, thermal reclaiming system; DHANAPROKASH (2009) 7’ x 14’ car bottom type 1800 degree heat treat furnace; INDUCTOTHERM 1250 KW, coreless induction melting system with (2) 5000 LB hydraulic tilting furnaces; INDUSTRIAL COMBUSTION car bottom type 1800 degree heat treat furnace; PALMER (2006) XL200, continuous mixing system; PANGBORN 34 CU FT tumblast cleaning machine; SPECTROLAB (2005) 15 element spectrometer; TINIUS OLSEN (2006) hydraulic tensile tester; RE-TOS (1999 REBUILT) W100, table type horizontal boring mill; UNION BFT-90/3-1, table type horizontal boring mill; HYD-MECH S-25A, horizontal saw; FORTUNE V-TURN-46, CNC turning center; WEBSTER & BENNETT 48” vertical turret lathe; MEUSER 4’ radial arm drill; (5+) assorted engine lathes; (3) KONE (2000) 10 & 3 ton x 40’ overhead bridge cranes; NORTH AMERICAN 10/5 ton x 80’ overhead bridge crane; STAHL 30 ton x 79’ overhead bridge crane; (2) QUINCY air compressors; GAYLORD gas fired ladle pre-heater; (5+) Geared bottom pour ladles; COMPLETE LAB & TESTING DEPARTMENT; COMPLETE PATTERN SHOP; LARGE OFFERING OF machining & fabricating equipment, forklifts, 4x4 GENIE lift, foundry support assets, factory support equipment & MORE!

FOUNDRY EQUIPMENT

- KLOSTER (2002) slick loop no bake molding system consisting of KLOSTER receiving hopper with supports and NOLTEC bin vent dust collector; KLOSTER sand heater/cooler/classifier with boiler, TRANE 30 ton chiller and blower; KLOSTER TYPE II articulating 1000 LBS/minute continuous mixer with pumps; KLOSTER barrel type mold rollover with hydraulic system; KLOSTER 3’ x 5’ compaction table; stub roller conveyor system with (14) 45” x 55” pattern carriers; stub roller conveyor with related transfer cars; A-frame closing station with QUIPTEC QER2KP2G1-52 4000 LBS capacity mold handler with controls, DEMAG electric hoist with pendant controls; (9) mold lines with (8) bottom board handling capacity each; (140) 42” x 48” bottom boards; (2) powered conveyor mold pouring lines with related self powered transfer carts; (4) powered mold cooling lines with (7) bottom board handling capacity each; fume exhaust hood; self propelled transfer car to mold dump; hydraulic mold dump system; bottom board return conveyor; s/n MS-007816-111

- (2) DHANAPROKASH (2009) 7’ X 14’ car bottom type heat treat furnace system with 7’ x 14’ self propelled car, 3 burners per side, KO lining, PLC controls, blower motor and controls, s/n 150010345270-002; 150010345270-002

- GUDGEON (2007) TF3000 THERMFIRE thermal re-claimer with (4) 700,000 BTU burners; (2) blowers and motors; XYCOM controls; EVAPCO cooling tower; 9000 CFM pulse bag type dust collector with de-fuser, TWIN CITY 917 RBA-SW 30 hp blower s/n 1158

- PALMER (2006) XL200 continuous mixer with CE CAST ECH300 electric sand heater with controls, PALMER oxide feeder s/n PF393

- INDUCTOTHERM CORELESS INDUCTION MELTING SYSTEM consisting of INDUCTOTHERM POWER TRAK 1250-10 R 1250 KW 1200 HZ power supply; (2) 5000 LBS capacity transite box hydraulic tilting furnaces with stands hydraulic system and piping; water system with pumps; s/n 95G-44975-246-11

- PRENTICE (REBULIT 2008) #125 hydraulic arm casting manipulator; s/n n/a

- G/K 15' x 40" vibratory table with drive and motor, s/n n/a

- G/K VM120 VIBRAMILL lump crusher with drive and motor, s/n n/a

- MACAWBER 4/4 pneumatic sand transporter with controls, s/n n/a

- HOT SAND RETURN HANDLING system consisting of MFG UNKNOWN (2009) water cooled screw type conveyor with water jacket and drive; SIMCO 2’ X 6’ screen with drive and water cooled jacket, s/n n/a

- KLOSTER sand cooler/classifier with blower and motor and EVAPCO outdoor cooling tower, s/n n/a

- MFG UNKNOWN magnetic cross belt separator, s/n n/a

- RETURN SAND approx. 80’ bucket elevator with drive and motor, s/n n/a

- (2) MFG UNKNOWN approx. 180 TON capacity sand holding silos with supports; return sand belt conveyor with drive and motor, s/n n/a

- NOLTEC receiving hopper with NOLTEC bin vent dust collector, s/n n/a

- NOLTEC 30 C.F. sand transporter s/n 1656AB

- WARD 25,000 CFM, 75 HP pulse type dust collector with blower and motor and controls, s/n n/a

- WHEELABRATOR 5000 CFM, 15 HP pulse type dust collector with blower and motor and controls, s/n n/a

- GAYLORD 400FS-FD-44SPEC-54/66 gas fired ladle pre-heater, s/n n/a

- (3) TEEMARK 5000 LBS capacity bottom pour geared ladles, s/n n/a

METALLURGY LAB

- TINIUS OLSEN digital hydraulic tensile tester s/n 205969

- TINIUS OLSEN IMPACTOR impact tester s/n 78458

- BARNSTED THERMOLINE 30400 digital electric lab oven with microprocessor control, s/n n/a

- BARNSTED THERMOLINE FB1315M digital electric lab oven with microprocessor control, s/n 1256050246354

- TYLER RO-TAP MODEL E digital lab test sieve shaker with sieves, s/n n/a

- SPECTROLAB (2004) LAVFCO1A digital spectro-photometer metal analyzer with Fe, Al, Cu, Ni, Co, Mg, Ti, Sn, Pb and Zn detecting capacity, 18 second average test time, s/n 117269/04

- COLE PARMER 12107-10 POLYSTAT digital bench type heated circulating bath, s/n G57951

- COLE PARMER 1283-60 POLYSTAT digital bench type chiller with -20 to -60 degrees C capacity, immersion probe, s/n A06400848

- DIETERT 400-A-MD1 bench type tester s/n 7021

CONVENTIONAL MACHINE TOOLS

- (2) WEBSTER & BENNETT 48” vertical turret lathe with 48” diameter 4 jaw chuck, hex rail head and controls, s/n n/a

- RETOS (REBUILT 1999) W100 4" table type horizontal boring mill with 49” x 49” table, 4” spindle, travels 48”-vertical, 48”-cross, 60” longitudinal, outboard support, 4 axis DRO, s/n 0241-99

- TOS TRENCIN (1999) SN400N/1000 engine lathe with 18" swing, 48" between centers,14” 4-jaw chuck, taper attachment, in/mm threading, FAGOR 2 axis DRO, s/n 68004010000043

FINISHING DEPARTMENT

- PANGBORN 34GNIM 34 CU FT shot blast machine with floor loader, 30 HP blast wheel, 1 piece door, separator and shot system, WHEELABRATOR approx. 15,000 CFM, 50 HP pulse type dust collector, approx. 30” x 45’ discharge belt conveyor with drive, s/n 898

- (2) QUINCY QSI-500 QSI500ANA41FC air cooled screw type air compressors s/n 91932H; 91831H

- QUINCY QSI-1000 air cooled screw type air compressor s/n n/a

MATERIAL HANDLING

- NORTH AMERICAN 10/5 TON capacity top running double girder bridge crane with approx. 80’ span, pendant controls, s/n n/a

- KONECRANE 10 TON capacity top running single girder overhead bridge crane with approx. 45’ span, pendant controls, s/n 299199

- KONECRANE 10 TON capacity top running single girder overhead bridge crane with approx. 42’ span, pendant controls, s/n n/a

- KONECRANE 3 TON capacity top running single girder overhead bridge crane with approx. 40’ span, pendant controls, s/n 301152