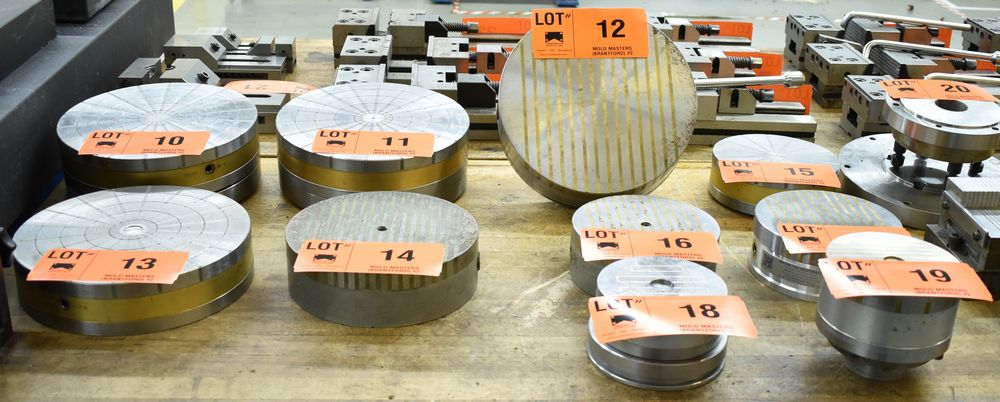

Mold Masters (Brantford) #2

High Precision CNC Grinding & Machining Equipment

Date

Wednesday, April 8, 2020

Start Time

10:30 AM EDT

Inspection

BY APPOINTMENT ONLY. Please email [email protected] to set a date and time.

Removal

BY APPOINTMENT ONLY. Please email [email protected] to set a date and time.

Industry

*IMPORTANT NOTE REGARDING THE AUCTION*

We are doing our best to ensure our staff and customers are as safe as possible. If you wish to inspect the assets, we ask that you make an appointment so we may take necessary precautions to maintain health and safety protocols. Please maintain your distance between yourself and others and please DO NOT attend if you are experiencing any symptoms of illness or have been exposed to someone who has, or have travelled outside of Canada in the last month.

If you wish for more information but cannot or do not wish to travel, we would be happy to provide an inspection via video and have someone available to answer any questions you may have. Please contact our office at 416.962.9600 or email [email protected] for more details. (Please allow 24 hrs for a response.)

FEATURING: MATSUURA (2002) MAM 72-3VS, CNC multi-pallet high speed horizontal machining center w/ 40 station pallet changer, 120 ATC, coolant thru spindle, FANUC CNC control, etc.; STUDER (2000) CNC high precision universal cylindrical grinder w/ thread grinding capability; (2) KELLENBERGER KEL-VARIA UR 175/1000, CNC high precision universal cylindrical grinders; EWAG AG (1996) RS 09, high precision tip grinder; NAKAMURA (2007) SC-300, CNC turning center w/ FANUC CNC control; (2) HARDINGE CS-65, CNC turning centers w/ FANUC CNC controls; KITAMURA (2000) MYCENTER-2Xi, twin pallet CNC high speed vertical machining center; MATSUURA MC-800VF, 4-axis CNC vertical machining center; PARLEC TMM 900, digital tool presetter; DECKEL precision tool room grinder; LAPMASTER bench top lapping/polishing unit; ASSORTMENT OF precision tooling and machine accessories, butcher block shop tables, granite surface tables, vertical bandsaw, shot blast cabinet, rotary indexing units & MORE!

CNC VERTICAL MACHINING CENTERS

- MATSUURA (2002) MAM72-3VS simultaneous 5-axis CNC vertical machining center with FANUC SERIES 16i-M CNC control, Ø11.81” x 9.84” h max work piece capacity, Ø 5.11" pallets, travels X-26.77", Y-15.74", Z-24.60", B - 220 degrees, C - 360 degrees, BT-40 spindle taper, 120 station ATC expandable to 240 stations, 40 station automatic pallet changer with robotic pick & place loading robot and operator setup station, touch tool wear indicator, high pressure coolant through spindle, CHIP BLASTER high pressure, high volume coolant system, MOSNIC chip conveyor with tank and coolant filtration, KURODA DAIKIN spindle chiller, MIST BLASTER mist collector, 200-220v/3ph/50-60hz, s/n 020415146

- MATSUURA MC-800VF 4 axis CNC vertical machining center with YASNAC SYSTEM i80 CNC control, 45.27" X 16.14" table, travels X-31.50", Y-17.32", Z-19.09", speeds to 8,000 rpm, BT 40 spindle taper, 30 station ATC, TSUDAKOMA 4th axis CNC rotary table with tailstock, high pressure coolant, spindle chiller, 200-220v/60hz/3ph, s/n 950711406

- KITAMURA MYCENTER 2xi twin pallet CNC vertical machining center with FANUC 16i-M CNC control, 31" X 14" pallets, travels X-20", Y-14", Z-18", speeds to 10,000 rpm, CAT 40 spindle taper, 24 station ATC, coolant, 200-220v/60hz/3ph, s/n 07391

- PARLEC PARSETTER TMM900 digital optical tool pre-setter with TOOL CHECK 200 DRO, DYMO thermal printer, s/n 97468-0896

CNC TURNING CENTERS

- NAKAMURA SC300 CNC turning center with FANUC SERIES 21i‐TB CNC control, KITAGAWA B-210 10”-3-jaw chuck, 12 station turret, hydraulic tailstock, parts catcher arm, chip conveyor, coolant system, mist extractor, chip conveyor, 200-220v/50-60hz/3ph, S/N: S310304

- HARDINGE CS‐65 CNC LATHE with GE FANUC SERIES 18‐T CNC control, 10” 3-jaw chuck, 10 station turret, hydraulic tailstock, chip conveyor, CHIP BLASTER high pressure high volume coolant system, mist extractor, chip conveyor, 230v/50-60hz/3ph, S/N: CLT‐466‐C65

- HARDINGE CS‐65 CNC LATHE with GE FANUC SERIES 18‐T CNC control, collet chuck, 12 station turret, hydraulic tailstock, tool checker arm, chip conveyor, CHIP BLASTER high pressure high volume coolant system, mist extractor, chip conveyor, 230v/50-60hz/3ph, S/N: CL‐756‐B65

TOOL & CUTTER GRINDERS

- EWAG RS-09 precision PCD and tungsten carbide tool grinder with RS profile projector, 3hp variable speed grinding spindle with speeds to 8000 rpm, -6 to +24 degree spindle tilting, 8.66” stroke range, 0 to 1.38” sleeplessly adjustable oscillation stroke, 30/60 strokes/minute, 6.10”x8.07” table with 240 degree swivel angle and 2.36” travel, coolant, paper filtration, mist extractor, 460v/3ph/60hz, s/n 099603020

- DECKEL KOD526/XS/XF/S12 universal tool and cutter grinder with collets and stand, s/n 99-8593

CNC GRINDERS

- STUDER S40CNC CNC universal cylindrical grinder with FANUC SERIES 16-T CNC control, 11.81” swing, 39.37” between centers, 19” wheel, 8” magnetic chuck, wheel dresser, coolant, paper filtration, mist extractor, 400v/3ph/60hz, s/n 011.0448.90.075

- KELLENBERGER KEL‐VARIA UR 175/1000 CNC universal cylindrical grinder with MOVOMATIC ES400 KELCO 90 CNC control, 8" CHUCK 39.40" between centers, travels X-12.90", Z-45", -10/+110 degree standard work head, -210/+30 degree swivel system, spindle speeds to 800 rpm, 16"x2.5" wheel, 10 hp head, coolant filtration, 460v/3ph/60hz, S/N: 650012

- KELLENBERGER KEL‐VARIA UR 175/1000 CNC universal cylindrical grinder with MOVOMATIC ES400 KELCO 90 CNC control, 8" CHUCK 39.40" between centers, travels X-12.90", Z-45", -10/+110 degree standard work head, -210/+30 degree swivel system, spindle speeds to 800 rpm, 16"x2.5" wheel, 10 hp head, coolant filtration, 460v/3ph/60hz, S/N: 650032

CONVENTIONAL MACHINE TOOLS & EQUIPMENT

- TOS SN50C gap bed engine lathe with 22” swing over bed , 28” swing in the gap, 78” between centers, 2” spindle bore, 10” 4 jaw chuck, speeds to 2000RPM, in/mm, threading, steady rest, coolant, s/n: 085020980229 (LOCATED IN ETOBICOKE, ONTARIO)

- (3) ACER DYNAMIC 1440G engine lathes with 14” swing, 40” between centers, 1-9/16” spindle bore, speeds to 2000 rpm, in/mm threading, s/n n/a (LOCATED IN WINDSOR ONTARIO)

- (2) ACER DYNAMIC 1340G engine lathes with 14” swing, 40” between centers, 1-9/16” spindle bore, speeds to 2000 rpm, in/mm threading, s/n n/a (LOCATED IN WINDSOR ONTARIO)

- FLEX ARM pneumatic tapping arm, with stand, s/n n/a

- PEENMATIC PM750S precision sand blast cabinet with (4) blast media hoppers, media recovery, s/n FVG2001/750-2231

- LAPMASTER LAPMASTER 15 wet lapping machine with 15” table, speeds to 6000 rpm variable speed, s/n 220999

- (2) FRANKLIN ½ hp variable speed bench type speed lathes with 6” 3-jaw chuck, IMDS digital variable speed control, 110v/60hz/1ph, s/n n/a

- SCHAUER LA2B 1 hp 2 speed bench type speed lathe with 6” 6-jaw chuck, 220v/60hz/3ph, s/n 40391M

- MOTIVATION 4,000 lbs capacity free standing jib crane with 2 ton BUDGIT electric chain hoist 15’ span, 10’ height under the hook, s/n n/a

- GENERAL MODEL 789 jointer planer, s/n 730715 (LOCATED IN WINDSOR ONTARIO)