Piper Precision, Inc.

Late Model HAAS CNC Machining Facility

Date

Wednesday, May 31, 2017

Start Time

10:30 AM CDT

Inspection

Tuesday, May 30 from 9:00 A.M. to 5:00 P.M. and morning of auction to start of auction.

Removal

Small items: Thursday, June 1 by 5:00 P.M.

Remaining items: BY APPOINTMENT ONLY. Friday, June 9 by 5:00 P.M.

Industry

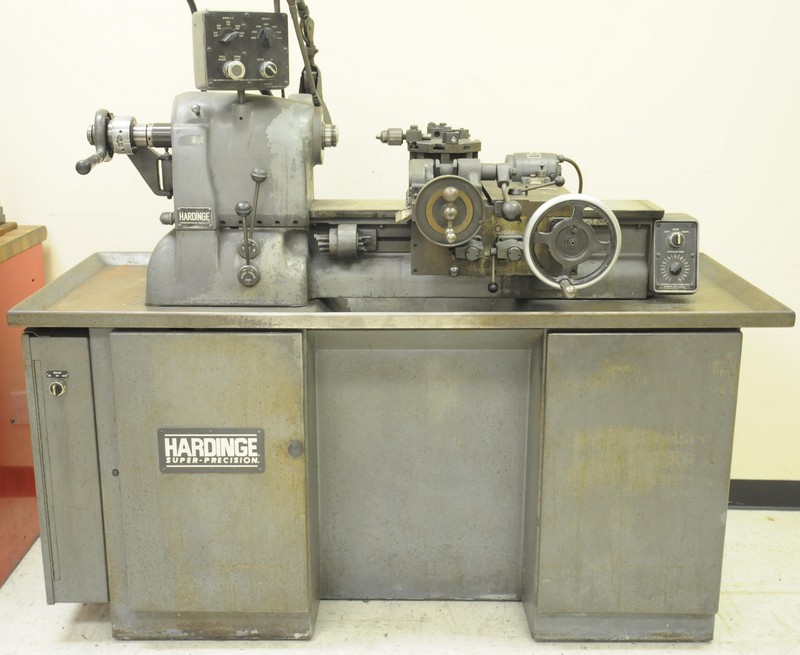

FEATURING: HAAS (10/2012) ST-20, CNC turning center; (2) HAAS (10/2012) ST-10, CNC turning centers; HAAS (03/2006) SL-20T, CNC turning & live milling center; HAAS (01/2006) SL-10, CNC turning center; (2) HAAS (10/2012) BAR 48A, servo bar feeders; HAAS (03/2006) BAR 300, servo bar feeder; HAAS (08/2004) VF-2SS, 4 axis CNC high speed vertical machining center; ONA PRIMA S-250+AWF, CNC wire EDM; HYD-MECH (1999) H-14, automatic horizontal saw with bundling; (2) EXCEL SL-320HS, CNC turning centers; DAINICHI F25M, CNC turning center; (3) SMW (10/2000) SPACESAVER, servo bar feeders; POWER GRIP (2012) pneumatic sheet lifter; MITUTOYO (BRAND NEW) LH-600B, digital linear height gauge; ADVANTAGE (2002) temperature control unit; HELI 4600lb, outdoor LPG forklift; HARDINGE SUPER PRECISION, tool room lathe; LEBLOND engine lathe; SUPERMAX universal milling machine; HUSKY portable air compressor; ROCKWELL hardness tester; S-T INDUSTRIES optical comparator; LARGE OFFERING OF precision tooling, machine accessories, HAAS 4th axis CNC rotary table, inspection department, shot blast equipment, grinders, horizontal saws, milling machines, jib cranes, KURT vises, LISTA type tool cabinets, assorted transformers, BRASS & STAINLESS STEEL bar stock inventory, cantilever racking & MORE!

CNC TURNING CENTERS

- HAAS (10/2012) ST20 CNC turning center with HAAS CNC control, 8” 3 jaw chuck, collet chuck, 32” swing over bed, 15” max. turning diameter, 21” max. turning length, travels: X - 9.3", Z - 21 ", 2” spindle bore, 12 station turret, speeds to 4000 RPM, 20 HP spindle motor, coolant, chip conveyor, s/n: 3093628

- HAAS (10/2012) ST10 CNC turning center with HAAS CNC control, 6” 3 jaw chuck, collet chuck, 28” swing over bed, 14” max. turning diameter, 16” max. turning length, travels: X - 7.88", Z - 16 ", 2” spindle bore, 12 station turret, speeds to 6000 RPM, 15 HP spindle motor, coolant, chip conveyor, s/n: 3093788

- HAAS (10/ 2012) ST10 CNC turning center with HAAS CNC control, 6” 3 jaw chuck, collet chuck, 28” swing over bed, 14” max. turning diameter, 16” max. turning length, travels: X - 7.88", Z - 16 ", 2” spindle bore, 12 station turret, speeds to 6000 RPM, 15 HP spindle motor, coolant, s/n: 3093747

- HAAS (03/2006) SL20T CNC turning & live milling center with HAAS CNC control, 8” 3 jaw chuck, collet chuck, 23” swing over bed, 10” max. turning diameter, 24” max. turning length, 2” spindle bore, 12 station turret, live tooling, speeds to 4000 RPM, 20 HP spindle motor, coolant, chip conveyor, tail stock, tool checker, s/n: 72620

- HAAS (01/2006) SL10 CNC turning center with HAAS CNC control, 6” 3 jaw chuck, collet chuck, 16” swing over bed, 11” max. turning diameter, 14” max. turning length, 2” spindle bore, 12 station turret, speeds to 6000 RPM, 15 HP spindle motor, coolant, chip conveyor, tool checker, s/n: 72378

- (2) EXCEL SL-320 HS CNC turning centers with GE FANUC Series O-T CNC control, 10” chuck, 18” swing over bed, 10” max. turning diameter, 24” max. turning length, 12 station turret, speeds to 4000 RPM, 25 HP spindle motor, coolant, chip conveyor, tail stock, s/n: SL3-0417, SL3-1237

- DAINICHI F25 CNC turning center with FANUC Series 18-T CNC control, 8” 3 jaw chuck, 19” swing over bed, 11” max. turning diameter, 22” max. turning length, 2” spindle bore, 16 station turret, speeds to 3000 RPM, 20 HP spindle motor, coolant, tail stock, s/n: 28460

CNC VERTICAL MACHINING CENTER

- HAAS (08/2004) SUPER VF2SS CNC vertical machining center with HAAS CNC control, 36”x14” table, travels: X – 30”, Y – 16”, Z – 20”, speeds to 12,000 RPM, 30 HP, 40 taper spindle, 24 station ATC, coolant, HAAS CNC HA5C 4th axis rotary indexer, s/n: 37111

AUTOMATIC BAR FEEDERS

- (2) HAAS (2012) SERVO BAR 300 automatic bar feeder, s/n: 93929, 93948

- HAAS (2006) SERVO BAR 300 automatic bar feeder, s/n: 91769

- SMW SPACESAVER 2003 automatic bar feeder, s/n: 011-359

- (2) SMW SPACESAVER 2000 automatic bar feeder with pendant control, s/n: 8.8-727, 8.8-728

CNC WIRE EDM

- ONA PRIMA S250+AFW CNC wire EDM with ONA CNC control with pendant, travels: X – 13”, Y – 9”, Z – 7”, ADVANTAGE DIGITAL CHILLER, dielectric tank with filtration, s/n: 10090

AUTOMATIC HORIZONTAL BAND SAW

- HYD-MECH (1999) H-14 automatic horizontal band saw with PLC control, 24”x16” cutting capacity, 1.25”x168” blade, 89”x31” roller conveyor, s/n: 50599068

CONVENTIONAL MACHINE TOOLS

- SUPERMAX YCM-2GS vertical milling machine with 51”x11” table, speeds to 3800 RPM, NEWALL DP7 3 axis DRO, coolant, KURT 6” machine vise, s/n: 4043748

- MFG. UNKNOWN vertical milling machine with 42”x9” table, speeds to 4200 RPM, 3 HP, R8 collet, s/n: M0029

- HARDINGE HC SUPER PRECISION turret lathe with 15” swing over bed, 12” between centers, speeds to 3600 RPM, 8 station turret, s/n: n/a

- LEBLOND engine lathe with 16” swing over bed, 56” between centers, speeds to 2400 RPM, inch/metric threading, 10” chuck, steady, s/n: n/a

- MFG. UNKNOWN vertical turret lathe with 5 station turret, 30” diameter chuck, s/n: n/a

- WILTON horizontal band saw with 15”x9” capacity, s/n: 0010309

- HAMMOND CHIP BREAKER CM-6 tool grinder, s/n: 761

- HAMMOND tool grinder, s/n: n/a

- BURR-KING Model 362 vertical sander

- BALDOR/KALAMAZOO vertical sander

- BALDOR 6” double end pedestal grinder

- DELTA SHOPMASTER bench type drill press

- MAKITA 14” abrasive cut off saw

- MFG. UNKNOWN sand blast cabinet

MATERIAL HANDLING

- HELI (2012 WITH ONLY APPROX 490 HOURS) CPYD25C-TY5 LPG forklift with 4600 LB capacity, 185” vertical lift, 3 stage mast, side shift, outdoor tires, s/n: 230250S4815

- ADVANCE CRANE 1 ton capacity free standing jib crane with 12’ span, DAYTON 1 ton electric hoist

- WOODS (2012) POWR-GRIP PT10HV11AIR pneumatic sheet lifter with 1500LB capacity, 150LB per pad, s/n: 20120076

INSPECTION EQUIPMENT

- KEYENCE IM-6020 image dimension measuring system s/n: CC112120

- MITUTOYO LH-600B linear height gauge

- SCHERR-TUMICO Model 20-4400 14” optical comparator, s/n: HA972404

- ROCKWELL bench type hardness tester

- 72”x48”x8.5” granite surface plate with stand

- 48”x24”x6” granite surface plate with stand

ALSO:

LARGE QUANTITY of raw material consisting of non-ferrous and ferrous bar stock, heat-treated annealed stainless steel, aluminum, brass and composite; cantilever racks; tool cabinets; work benches; SIZEABLE STOCK of machine tooling including CAT-40 tool holders, 5C collets, spring collets; extensive inspection department with MITUTOYO and STARRETT outside micrometers, Vernier calipers, dial bore gauges, refractometers; MAJOR combination safe; office furniture; laptop computers, business machines & MUCH MORE!