Surplus to the Ongoing Operations of

Torpedo Specialty Wire

High Performance Speciality Wire Manufacturer

Date

Tuesday, November 1, 2016

Start Time

10:30 AM EST

Inspection

Monday, October 31 from 9:00 A.M. to 5:00 P.M. and morning of auction to start of auction.

Removal

Small items: Wednesday, November 2 by 5 PM

Remaining items: Tuesday, November 15 by 5 PM

Industry

70,000+ SQ FT Manufacturing Facility Featuring: (5) Rod breakdown lines; WATERBURRY FARREL 3 stand flat wire rolling mill line; (8) Flat wire rolling mill lines; (3) Fine wire drawing lines; (3) SYNCRO wire annealing lines; (3) 10 strand wire annealing lines; (12) wire plating lines; (13) In-line wire plating systems; Clad wire production line; (2) VAUGHN 4” roller stands; Waste water treatment system; INDUSTRONICS 1500 degree bell furnace; HUGE ASSORTMENT OF butt welders, precision testing equipment, INSTRON digital tensile tester, LAB equipment, chillers, spare machine parts & accessories, machine shop equipment, fabricating equipment, dust collectors, late model air compressors, assortment of forklifts & vehicles, SWEED wire scrap choppers, raw material, filter press, general plant support equipment & MUCH MORE!

WIRE DRAWING LINES

- VAUGHN MOTOBLOX HRV 6/7HR 6-block wire drawing line with RELIANCE drive controls; 24"/18" blocks; 28" finish with riding stripper; (6) 30 HP motors; overhead un-coiler; traversing spooler re-winder; s/n 9024

- VAUGHN MOTOBLOX 6/7HIV wire drawing line with 14"/11" blocks; 15" finish with riding stripper; 10 HP motors; re-winder; s/n 10171

- SYNCRO (REBULIT 2013 OVER $110K) F13 13-die rod breakdown line with 300 HP motor; HALL INDUSTRIES traversing spooler re-winder; s/n F13/104

SPECIALTY FLAT WIRE ROLLING MILL LINES

- RM-2 flat wire rolling mill line with .004" to .020" thickness capacity; .030" to .125" width capacity; 30:1 max width to thickness ratio; consisting of: 1" horizontal rolling mills; 4-strand accumulator/tensioner; 10' annealing chamber; FILM TECH F-443 twin spindle spooler; down stream tensioner; power uncoiler & power pay-off; s/n n/a

- RM-3 flat wire rolling mill line with .004" to .020" thickness capacity; .030" to .100" width capacity; 20:1 max width to thickness ratio; consisting of: 1" horizontal rolling mills; 4-strand accumulator/tensioner; 10' annealing chamber; down stream tensioner; power uncoiler & power pay-off; s/n n/a

- RM-4 flat wire rolling mill line with .004" to .020" thickness capacity; .030" to .100" width capacity; 20:1 max width to thickness ratio; consisting of: 1" horizontal rolling mills; 4-strand accumulator/tensioner; 10' annealing chamber; down stream tensioner; power uncoiler & power pay-off; s/n n/a

- RM-5 flat wire rolling mill line with .004" to .020" thickness capacity; .030" to .100" width capacity; 20:1 max width to thickness ratio; consisting of: 1" horizontal rolling mills; 4-strand accumulator/tensioner; 10' annealing chamber; down stream tensioner; power uncoiler & power pay-off; s/n n/a

- RM-6 flat wire rolling mill line with .004" to .020" thickness capacity; .030" to .100" width capacity; 20:1 max width to thickness ratio; consisting of: 1" horizontal rolling mills; 4-strand accumulator/tensioner; 10' annealing chamber; down stream tensioner; power uncoiler & power pay-off; s/n n/a

- RM-7 flat wire rolling mill line with .004" to .020" thickness capacity; .060" to .250" width capacity; 30:1 max width to thickness ratio; consisting of: ROUSCH 2" horizontal rolling mill; 1" secondary rolling mill; 4-strand accumulator/tensioner; 10' annealing chamber; down stream tensioner; power uncoiler & power pay-off; s/n n/a

- RM-8 3-strand flat wire rolling mill line with .004" to .040" thickness capacity; .060" to .300" width capacity; 40:1 max width to thickness ratio; consisting of: (3) WATERBURY FARREL 4" horizontal rolling mills; 4-strand accumulator/tensioner; annealing chamber; down stream tensioner; 20 & 25 HP VFD's; power uncoiler & power pay-off; s/n n/a

- RM-9/RM-10 tandem flat wire rolling mill line with .004" to .020" thickness capacity; .030" to .125" width capacity; 20:1 max width to thickness ratio; consisting of: (2) AD-1526DC1300-TOR-US rolling mills; 4-strand accumulator/tensioner; annealing chamber; down stream tensioner; (2008) DURA SPEED VFD's; power uncoiler & power pay-off; s/n n/a

MEDIUM AND FINE WIRE DRAWING & ANNEALING LINES

- SYNCRO C12 12-die medium wire drawing and annealing line consisting of RESISTONEAL annealer; dip tank; annealing oven; SYNCRO re-spooler; s/n 749 8Y43.9

- SYNCRO (REBUILT 2013 OVER 41K USD) C12 12-die medium wire drawing and annealing line with SECO MENTOR II touch screen PLC control; DURAPULSE GS3-40/50 digital VFD drive; consisting of RESISTONEAL annealer; spool carrier; dip tank; annealing oven; SYNCRO re-spooler; s/n n/a

- SYNCRO C12 12-die medium wire drawing and annealing line with DURAPULSE GS3-40/50 digital VFD drive; consisting of RESISTONEAL annealer; spool carrier; dip tank; annealing oven; SYNCRO re-spooler; s/n n/a

- SA #1 electric multi strand fine wire annealing line with 3-zone digital heat control; consisting of 16 tube capacity, 20' x 37" electric annealing oven with 1750 degrees F max temperature; 125 FPM capacity; quench tank; 10- station floor type uncoilers; roll type accumulator; 16-station spooler re-winder; s/n n/a

- SA #2 electric multi strand fine wire annealing line with 3-zone digital heat control; consisting of 16 tube capacity, 18' x 37" electric annealing oven with 1750 degrees F max temperature; 125 FPM capacity; quench tank; 10- station floor type uncoilers; roll type accumulator; 16-station spooler re-winder; s/n n/a

- SA #3 electric multi strand fine wire annealing line with 3-zone digital heat control; consisting of 24 tube capacity, 14' x 37" electric annealing oven with 1750 degrees F max temperature; 125 FPM capacity; quench tank; 10- station floor type uncoilers; roll type accumulator; COULTER & MCKENZIE C500 10-station spooler re-winder; s/n n/a

- SYNCRO BG16 16-die fine wire drawing and wire annealing line consisting of RESISTONEAL annealer; dip tank; annealing oven; SYNCRO re-spooler; s/n n/a

- SYNCRO BG16 16-die fine wire drawing and annealing line with retrofit DURAPULSE GS3-4025 digital VFD drive; consisting of RESISTONEAL annealer; dip tank; annealing oven; SYNCRO re-spooler; s/n n/a

- INDUSTRONICS single zone electric bell furnace with OMEGA digital temperature control; OMEGA temperature recorder; 1500 degrees F max temperature; 100 KW 2-station heater; s/n n/a

FINE WIRE PLATING LINES

- (13) HP1-HP13 (2008) fine & flat wire plating lines with PANELVIEW PLC touch screen controls; consisting of: standalone powered pay-off; roll type accumulator; composite clean and flux dip tanks; stainless steel electric melting pot with starter; programmable dip & air wipe coater; tensioner; spooler re-winder; s/n n/a

- RAPID POWER TECHNOLOGIES (REBUILT 2013 OVER 21K USD) #P7 fine wire plating line consisting of uncoiler stand; roll type accumulator; composite plating dip tanks; RAPID TECHNOLOGIES 3000 AMP rectifier; RAPID TECHNOLOGIES 1500 AMP rectifier; spooler re-winder; s/n n/a

- RAPID POWER TECHNOLOGIES #P1 fine wire plating line consisting of uncoiler stand; roll type accumulator; composite plating dip tanks; RAPID TECHNOLOGIES 2000 AMP rectifier; RAPID TECHNOLOGIES 1500 AMP rectifier; spooler re-winder; s/n n/a

- RAPID POWER TECHNOLOGIES #P2 fine wire plating line consisting of uncoiler stand; roll type accumulator; composite plating dip tanks; RAPID TECHNOLOGIES 2000 AMP rectifier; RAPID TECHNOLOGIES 1500 AMP rectifier; spooler re-winder; s/n n/a

- RAPID POWER TECHNOLOGIES #P4 fine wire plating line consisting of uncoiler stand; roll type accumulator; composite plating dip tanks; RAPID TECHNOLOGIES 2000 AMP rectifier; RAPID TECHNOLOGIES 1500 AMP rectifierpooler re-winder; s/n n/a

- RAPID POWER TECHNOLOGIES #P5 fine wire plating line consisting of uncoiler stand; roll type accumulator; composite plating dip tanks; RAPID TECHNOLOGIES 2000 AMP rectifier; RAPID TECHNOLOGIES 1500 AMP rectifier; spooler re-winder; s/n n/a

- RAPID POWER TECHNOLOGIES #P13 fine wire plating line consisting of uncoiler stand; roll type accumulator; composite plating dip tanks; RAPID TECHNOLOGIES 2000 AMP rectifier; RAPID TECHNOLOGIES 1500 AMP rectifier; spooler re-winder; s/n n/a

PRODUCTION SUPPORT EQUIPMENT

- VAUGHN combination heavy duty pointer stringer with 8-groove horizontal roll pointer; s/n n/a

- VAUGHN 10-groove horizontal roll pointer; s/n 10047

- VAUGHN 10-groove horizontal roll pointer; s/n 9771

- (2) KOLDWELD KBM5 portable cold welders with rolling stand; s/n n/a

- N22 SINGLE DIE finishing machine consisting of coil un-winder; single-block; roll accumulator; spooler re-winder; s/n n/a

- N20 SINGLE BLOCK drawing line with coil un-winder; single-block; roll accumulator; spooler re-winder; quench tank; s/n n/a

- (15+) MICROWELD J6S; J6C; J8S and J4S portable butt welders; s/n n/a

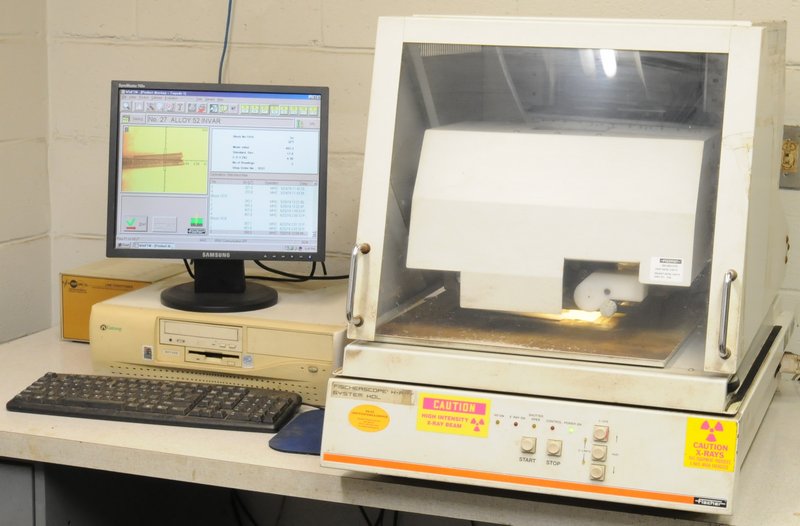

INSPECTION AND Q.A. EQUIPMENT

- FISCHER FISCHERSCOPE SYSTEM XDL-XYMZ, X-ray coating thickness measuring and analyzing system with PC WINDOWS based FTM control and data acquisition software; programmable X & Y axis table; s/n 01843788

- INSTRON 4411 digital bench type tensile and compression tester with 5KN; 1124 LBS cap; s/n 4411C4374

- TINIUS OLSEN H1KT bench type tensile and compression tester with WINDOWS PC based control and data acquisition software; 1KN; 220 LBS cap; s/n HIKT-0086

- NIKON V12 12" bench type optical comparator; s/n Q-534901

- MITUTOYO COMFILE standalone bench type digital wire thickness gauge with WINDOWS CE based touch screen control and data acquisition software; s/n n/a

- LASERMIKE 101 portable digital continuous laser micrometer with LASERMIKE 1000 DRO; WINDOWS PC based control and data acquisition software; s/n n/a

- (4) LASERMIKE 182 portable digital continuous laser micrometer; s/n n/a

- (2) BUHLER 1511 rotary table type lapper/polishers; s/n n/a

- BUHLER SURFMET I belt type lapper/polisher; s/n n/a

MATERIAL HANDLING

- DOOSAN (1999) GC30E-3 LPG forklift with 4,500 LBS capacity; 186" reach; 3-stage high visibility mast; side shift; hydraulic fork adjustment; cushion tires; s/n CV-02898

- DOOSAN (1999) GC15S-2 LPG forklift with 2,500 LBS capacity; 186" reach; 3-stage high visibility mast; side shift; hydraulic fork adjustment; cushion tires; s/n 3CV-02898

- CLARK (1995) GCX-40 LPG forklift with 6,800 LBS capacity; 170" reach; 3-stage high visibility mast; side shift; cushion tires; s/n GX710U-0026-9418FB

- CLARK ST30D 2,700 LBS capacity electric walk behind type forklift truck; s/n ST245-0015-5305FA

- SPEEDWAY 5 TON capacity single girder underslung bridge crane with approx. 20' span, approx. 40' runways, s/n n/a

MAINTENANCE DEPARTMENT

- THERMAL DYNAMICS (2004) CUTMASTER 51 portable plasma cutter with cables and gun; s/n 02843167

- MILLER (2005) MILLERMATIC 210 digital MIG welder with cables and gun; s/n LF471582B

- MILLER THUNDERBOLT AC/DC ARC welder with cables and gun; s/n n/a

- MILLER MAXSTAR 150STL portable TIG welder with case, cables and gun; s/n n/a

- LINCOLN IDEALARC DC-400 ARC welder with cables and gun; s/n n/a

- DOALL 36-W vertical band saw with 36" throat; 20" max cutting height; 36" x 30" sliding table; blade welder and grinder; s/n n/a

- LEBLOND REGAL engine lathe with 16" swing; 36" centers; speeds to 1010 RPM; 14" 3-jaw chuck; s/n NE6761

- CLAUSING 5913 engine lathe with 13" swing; 36" centers; speeds to 2000 RPM; 8" 3-jaw chuck; s/n 503546

- BRIDGEPORT SERIES I vertical turret milling machine with 9" x 42" table; speeds to 2700 RPM; ACURITE 2 axis DRO; s/n J9987

- CRAFTSMAN 20" heavy duty floor type drill press with 2 HP; speeds to 4200 RPM; s/n n/a

- SUNEX 5220 20 TON capacity hydraulic H-frame shop press; s/n n/a

- DAYTON electric combination 4" belt, 6" disc sander; s/n n/a

- NIAGARA 36" X 14 GA power rolls with stand; s/n n/a

FACTORY EQUIPMENT

- GARDNER DENVER (2011) ENDUR AIR 10 HP screw type air compressor; s/n ELA99CD090023

- GARDNER DENVER 30 HP screw type air compressor; s/n n/a

- LEROI CL50CUB 50 HP screw type air compressor; s/n 4487X282

- GARDNER DENVER RNC50AI refrigerated air dryer; s/n 1000002709700

- AIRCELL VF200 refrigerated air dryer; s/n 17721

- GARDNER DENVER 7.5 HP tank mounted piston type air compressor; s/n n/a

- CHARGEAIR 6 HP tank mounted piston type air compressor; s/n n/a

- THERMAKLEEN ULTRA 250E portable electric pressure washer; s/n n/a

- ABSOLUTE AIRE R344 HO W/E/AP air make up unit with 28,000 CFM capacity; s/n 13961

- KCH outdoor pad type horizontal flow composite chemical scrubber with 18,000 CFM capacity; 30 HP blower; s/n 15489

- TORRIT DONALDSON DFT2-8 outdoor canister type dust collector with (8) canister filters; 7.5 HP blower; s/n IG454494-01

- HURST GAS fired 25 HP/863 LBS/HR/150 PSI steam boiler; s/n V61-150-398

- WEIGH TRONIX WI-127 5,000 LBS capacity digital floor scale; s/n n/a

- TRANS CELL TI-500E 5,000 LBS capacity digital floor scale; s/n n/a

- ORION H66-12 automatic rotary stretch wrapper; s/n 8018145

- SCOTSMAN CM250E-1E floor type commercial ice maker; s/n 632S90-11L

- GENERAC SE-10000 portable gas powered generator with 10,000 W capacity; 110/220V; SUBARU ROBIN 18 HP V-twin engine with electric start; s/n n/a

- SWEED 5 HP scrap wire chopper with stand; s/n n/a

COMPOSITE SPOOL INVENTORY

- (14,000+) HAFNER K125- DIN 125 - composite spools with 4.9" flange diameter; 3.9" traverse width; 3.1" barrel diameter; 0.63" arbor hole; 4.9" overall width

- (600+) 6x4 composite spools with 6.0" flange diameter; 4.0" traverse width; 4.0" barrel diameter; 0.63" arbor hole; 4.8" overall width

- (15,000+) HAFNER K160- DIN 160 composite spools with 6.3" flange diameter; 5.0" traverse width; 3.9" barrel diameter; 0.87" arbor hole; 6.3" overall width

RAW MATERIAL COIL INVENTORY

- (6300 LBS) .219" diameter; C1006AK low carbon steel coil

- (6900 LBS) .340" diameter; C1006SK low carbon steel coil

- (26500 LBS) .351" diameter; C1006AK low carbon steel coil

- (5200 LBS) .304” diameter; C1006AK low carbon steel coil

ALSO:

(5) STANLEY VIDMAR tool cabinets with parts and tooling; spare parts inventory; (3)BAUSCH & LOMB binocular metallurgy microscopes; FISHER SCIENTIFIC binocular metallurgy microscope; (4+) LASERMIKE 182 digital continuous micrometers; METTLER TOLEDO & OHAUS balance scales; BUHLER lappers; MILWAUKEE portable band saw; MILWAUKEE reciprocating saw; RIDGID manual pipe threading set; BOSCH heavy duty electric hammer drill; heavy duty angle grinders; shop fans; barrel carts; oil pumps; spill trays; pneumatic pumps; eye wash stations; operator stands; toolboxes; waste bins; spare spoolers; lab and inspection equipment; office furniture, business machines and MUCH MORE!